UTS-TF03 Horizontal and vertical flammability tester is to determine

the linear burning rate and the afterflame/afterglow times, as well

as the damaged length of specimens. They are applicable to solid

and celluar materials that have an apparent density of not less

than 250kg/m3, determined in accordance with ISO 845. They do

not apply to materials that shrink away from the applied flame

without igniting.

The standard IEC 60695 UTS-TF03 met, specifies a small scale

laboratory screening procedure for comparing the relative burning

behavious of vertically or horizontally oriented specimens made

from plastic and other non-metallic materials, exposed to a

small-flame ignition source of 50W nominal power.

A rectangular bar-shaped test specimen is supported horizontally or

vertically by one end and the free end is exposed to a specified test

flame. The burning behaviour of the horizontally supported bar is

assessed by measuring the linear burning rate. The burning

behaviour of the vertically supported bar is assessed by measuring

the afterflame and afterglow times, the extent of burning and

dripping of flaming particles.

Horizontal and vertical flammability tester is applicable to solid and

celluar materials that have an apparent density of not less than

250kg/m3, determined in accordance with ISO 845. And plastic

materials used in consumer electric devices and appliances.

IEC60695,GB2408,UL 94,ISO 9772.3,ASTM D635,ASTM D3801,

ASTM D4804,ASTM D4986

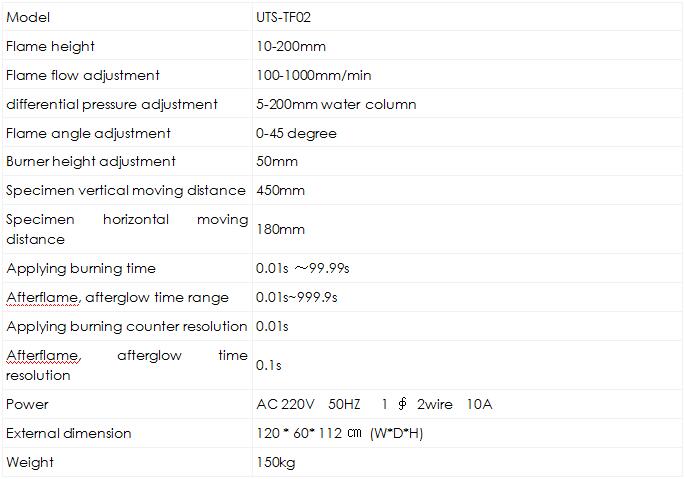

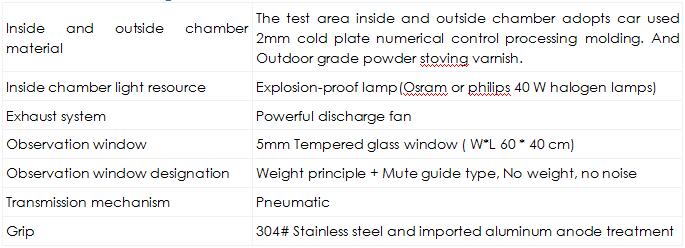

1. Adopt 2mm thick galvanized cold plate which shaped by Germany

trumpf CNC machining center, with beautiful and high grade

appearance.

2. Outdoor grade powder baking technology, which enhance anti-smog

corrosion resistance ability. High quality and without color changing.

3. Equipped with German imported temperature sensor used in

airplane and resistance to high temperature with longer service life.

4. Silent design toughened glass sliding observing window.

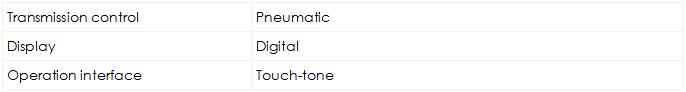

5. Step motor control stroke, accurate location and without buffer.

6. With the function of program parameter setting, the test parameters

can be programmed to be stored in the controller. PLC programmable

control to achieve One-click independent operation.

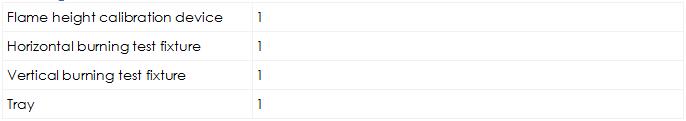

7. Special fixtures processed in high quality aluminum anode treatment.

8. Transmission type designation of Linear bearing with chrome plated

optical axis.

|

The structure designation

|

+86 152 6060 5085

+86 152 6060 5085 +86 152 6060 5085

+86 152 6060 5085