T001 Sharp edge tester is used to determine whether the accessible edges on child-related products are likely to cause potential risk of injury after normal use and reasonable abuse. Those child-related products include metal or glass edges on toys and other articles intended for use by children under 8 years of age.

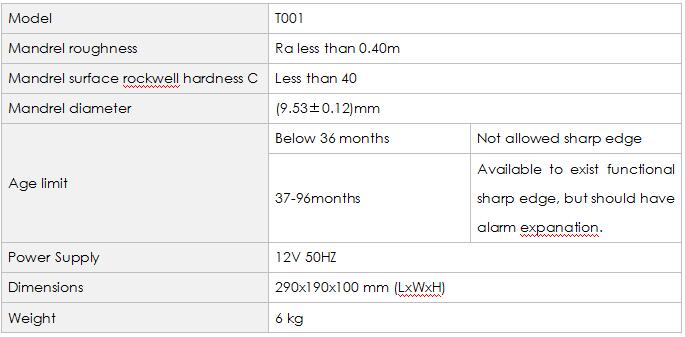

Key Specifications

Test Principle

A self adhesive PTFE tape is attached to a mandrel, which is then rotated for a single 360- degree revolution along the accessible edge being tested. If the tape is cut in half or longer in length (approx. 13mm), the edge is identified as a hazardous sharp edge.

Standards

16CFR 1500

EN 71-1

ASTM F963

ISO 8124-1

GB6675-2

Features

1. Metal material’s shell to ensure machine durable with long service life.

2. Extended type foot switch to make operation more convenient.

3. With force photoelectricity sensing indication function to ensure the testing force can be maintained at 1.35LB during testing, and avoid any error.

4. Equipped with external force adjustment function. Much more easy to adjust real force value to be same with display force value, which ensure the force value veracity in calibration.

5. Testing axis in steel material and harden processed with smooth surface, the max force applied vertically onto rotary axis during testing should be 1.35LB.

6. Tangent line speed should be 1.00±0.08 in / sec when testing axis at 75% rotary process.

7. Testing tape is pressure sensitive TYPE polytetrafluoroethylene(TFE) high temperature electrical insulation tape.

+86 152 6060 5085

+86 152 6060 5085 +86 152 6060 5085

+86 152 6060 5085