+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

The process of fabric pilling:

Hairiness --- fluffing --- entanglement --- forming a group --- tightening into a ball --- shedding

fluff:

Plush is initially produced along the longitudinal direction of the fiber. When the fabric is subjected to external friction, when the friction force is greater than the fiber strength or the friction or cohesion between the fibers, the fiber ends are pulled out to form loops and fluff, and the fluff is formed on the surface of the fabric to make the cloth surface lose its luster.

Tangled into balls:

In densely piled areas, loose fibers become entangled. When the fluff is exposed to a certain length, the fluff at a certain distance is tangled into a ball due to rubbing and friction, repeated stretching and retraction. The generated hair ball is not big and does not form a dead knot. One end of it is embedded in the fiber of the fabric and connected to the cloth surface. Hair balls are easy to hide dirt and affect the appearance of fabrics.

Hairball Growth:

The entangled fibers close together to form small balls, which are continuously growing by hanging from the surface of the fabric by strong fibers.

Hairball shedding:

When the fabric continues to be rubbed, the fibers connecting the hair balls will break due to repeated stretching and bending fatigue, and fall off from the cloth surface. People feel that whether the fabric is easy to pill is often inconsistent with the real situation. The fabric that is easy to pilling often gives people the feeling that it is not easy to pill because of the short life of the pilling.

Pilling test method

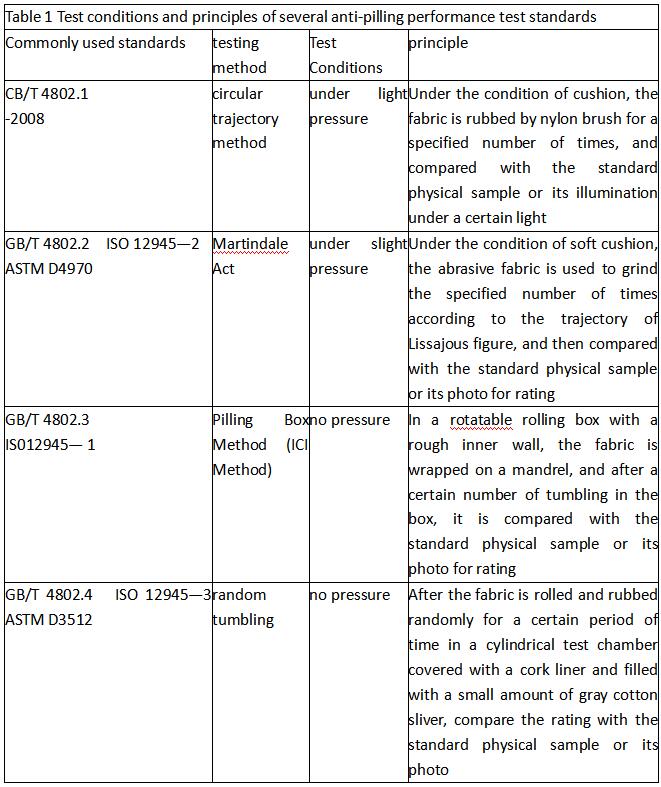

At present, commonly used anti-pilling test methods include circular track method, Martindale method, pilling box method and random tumbling method

Different standards adopt different test methods, such as: National Standard GB/T 4802.1-2008 "Determination of Pilling Properties of Textile Fabrics Part 1: Circular Track Method", National Standard GB/T 4802.2 "Determination of Pilling Properties of Textile Fabrics Martindale Method", National Standard GB/T 4802.3 "Pilling Box Method for Determination of Pilling Properties of Textile Fabrics", National Standard GB/T 4802.4 "Random Tumbling Method for Determination of Pilling Properties of Textile Fabrics", International Standard ISO 12945- 1 "Pilling Box Method for Determination of Pilling Properties of Textile Fabrics", International Standard ISO 12945-2 "Martindale Method for Determination of Pilling Properties of Textile Fabrics", International Standard ISO 12945-3 "Pilling Properties of Textile Fabrics Determination of random tumbling method", American Association for Materials Standard ASTM D3512 "Random Tumbling Method for Determination of Pilling Properties of Textile Fabrics", American Association for Materials Standard ASTM D4970 "Determination of Pilling Properties of Textile Fabrics Martindale Method", the above standards The test principles and test conditions of different methods are shown in Table 1.

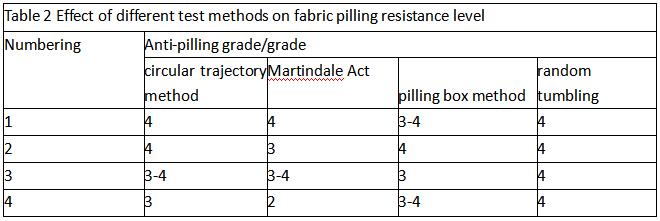

Due to different test methods, conditions, and principles, the anti-pilling performance of the same piece of fabric is quite different. The influence of different test methods on the anti-pilling level of fabrics is shown in Table 2.

Know more about the pilling tester,plesae click here.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com