+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

Clothes in the process of wearing, constantly subjected to friction, so that the fiber end of the fabric surface is drawn, band, hook, pull out, and the formation of hair feathers on the surface of the fabric phenomenon known as pilling. With the hair feathers are gradually pulled out, generally more than 5mm, and then subjected to friction, these fiber ends will be hooked to each other, winding the formation of irregular spherical phenomenon known as puckering.

Fabric with the use of continued friction, fiber ball gradually close, and make even in the fabric of the fiber by different directions of repeated folding, fatigue and even break, fiber ball will fall off from the surface of the fabric, but thereafter broken head end of the fiber hair feathers will continue to be drawn out in use and again formed fiber ball.

Generally speaking, wool and chemical fibers are easy to pilling, especially coarse combed wool fabric or imitation wool type of coarse combed fabric and cashmere fabric. From the point of view of yarn and tissue structure, yarn twist is small, more hair feathers, fabric structure is loose, there is a long floating line of twill, satin fabric is easy to pilling.

Pure cotton will also pilling! Because any surface of the fabric with hair, after use, friction, more or less pilling, but pure cotton pilling is not so obvious.

Chemical fiber fabric than cotton fabric is easy to pilling because the fiber strength of chemical fiber is greater than cotton, chemical fiber fabric pilling after the hair ball is not easy to fall off, a long time will be stubbornly stuck in the fabric surface. And cotton fabrics on the hair ball in the washing and friction gradually fall off, so that people formed a "cotton will not pilling" understanding.

Of course, cotton can also be divided into many grades, fiber length varies, fiber long cotton fiber end number is relatively small, fiber and fiber link end far from the formation of hair ball.

In addition, from the processing form, the general twist of the fiber is large, the holding force between the fiber and fiber, the fabric structure is relatively tight, flat, it is not easy to pilling. On the contrary, for example, the pilling phenomenon of blended fabrics is more serious, nylon, polyester, polypropylene, etc. is particularly serious, mainly because of the blended fabrics, the twist between the fibers and fibers is not the same, the surface of the fabric is easy to produce lint.

In order to ensure the safety and comfort of the garment, a piece of fabric, before it is made into clothes, will be subject to various tests, including pilling performance test.

The test method standards for pilling of garments are

GB/T 4802.1-2008 "Round track method

GB/T 4802.2-2008 "Modified Martindale Method

GB / T 4802.3-2008 "pilling box method

GB/T 4802.4-2020 "random tumbling method".

Although they all test the pilling degree of the fabric, but the above different methods apply to different garment fabrics, the working principle of the instrument is also different. No matter which method is used, the tested pilling performance is expressed in the form of grade, which is generally divided into 1~5 grades, the greater the number of grades, the less likely the clothes are to pilling. General standards specify that the indicators ≥ 3 levels for qualified products.

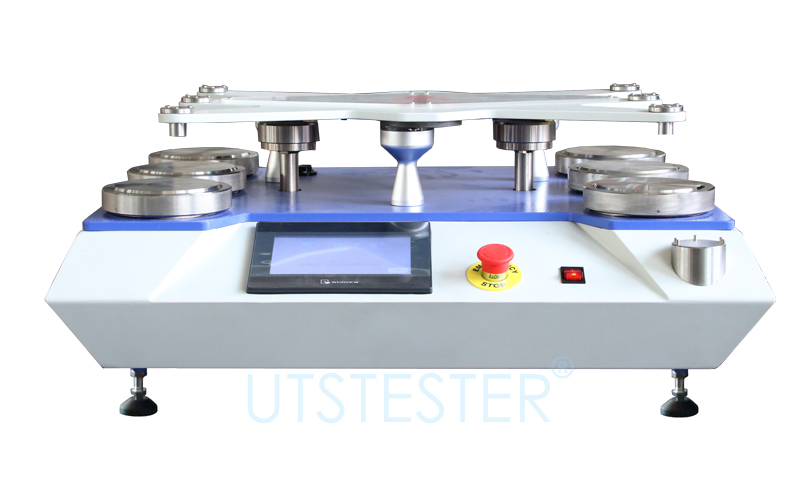

GB/T 4802.2-2008 "modified Martindale method" principle is under the specified pressure, the circular specimen around the central axis perpendicular to the plane of the specimen free rotation, to Liza Ru graphic trajectory with the same fabric or wool fabric abrasive friction, applicable to the bed class test.

GB/T 4802.3-2008 "puckering box method" is based on the principle that the specimen is mounted on a polyurethane tube and turned over arbitrarily in a wooden box with a constant speed and lined with cork. After a specified number of flips, the pilling and (or) pilling performance is evaluated by visual description. Applicable to the testing of sweater-type textiles.

GB/T 4802.4-2020 "random tumbling method" is based on the principle of random tumbling pilling box to make the fabric in a cylindrical test chamber lined with cork and filled with a small amount of gray short cotton tumbling friction. Domestic apparel product standards have not yet cited the method.

Clothes will pilling is the result of a combination of intrinsic and extrinsic factors. The intrinsic factors are related to the material and fabric structure of the fabric, and the extrinsic factors are the external force when people are wearing clothes. Therefore, the intrinsic factors can not change the case, you can reduce or avoid the occurrence of clothing pilling by reducing friction and other external effects.

For some easy to pilling clothing, such as wool sweaters, cashmere sweaters, wear when trying to avoid friction, especially with hard objects, such as friction with backpacks.

Also prevent hooking and pulling with sharp objects.

Washing can add some clothing softener, cashmere sweaters and wool sweaters can use special laundry detergent, which contains some anti-pilling additives.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com