Universal testing machine is most commonly used for quality control, inspection, physical test, mechanics research, material development and production environment. The testing is in a tensile or compression mode in a single frame or dual column. Extra test functions include tension, compression, bend, shear, bonding strength, break strength, peeling, tearing, cyclic and flexure, etc.

This test equipment is typically found in applications and industries, such as rubber, plastics, leather, metal, composites, nylon line, fabrics, paper, aviation, automotive, biomedical, elastomers, packaging, construction, petrifaction, aviation, petrifaction, electrician, vehicle, etc. Wildly used for R & D and production.

Capacities for this model ranges from low-load forces of 10N up to high capacity 10KN with 2 optional stroke 11oo mm & 900 mm as well as the customized stoke.

Features

1.The transmission system adopts imported AC servo drive system, high-end mute planetary reducer, synchronous belt wheel and imported precision ball screw assembly. The instrument beam moves smoothly and the noise is low; High elongation accuracy.

2. The instrument column is made of aluminum alloy profiles. The surface of the instrument is treated with high temperature curing spray, which is resistant to scratches and is not easy to fade.

3. Various protective measures are adopted for the instrument:

The protection device of the upper and lower limit of the beam;

Clamp protection device;

Set up displacement and load limit software protection;

Sensor overload protection;

Protection of sample load software;

Overcurrent, overpressure protection.

The main components are monitored in real time.Therefore, the instrument is safer and more reliable.

4. The instrument is equipped with high precision sensor for imported load, 24 bits A/D at high speed, and the effective collection frequency reaches 1000Hz.

5, This instrument uses open architecture, the user can edit the required test procedure, test report, data analysis formula according to the categories and characteristics of the test material, so as to meet the requirements of the test method, The hardware and software of the instrument adopt a piece structure, which can be used freely to complete different test requirements. The man-machine dialogue interface operates, guides the tester to complete the test, and can easily upgrade and maintain the instrument through online support.

6. The instrument provides a variety of personalized automatic modes.When using the electric control fixture, the test startup can be set to automatic starting and pre-tensioning of the clamping device, and the automatic clamping device can be set after the test.The device holds the distance digital setting and automatically locates.

7. The instrument host adopts touch screen control, which is easy to operate and has built-in thermal printer.

8. The device can be controlled by tablet computer, wireless wifi control or via android phone.

Standards

GB/T3923.1 (Equivalent to ISO13934.1)

GB/T3923.2 (Equivalent to ISO13934.2)

GB/T3917.2 (Equivalent to ISO13937.2)

GB/T3917.3 (Equivalent to ISO9073.4)

GB/T13772.1(Equivalent to ISO13936.1)

GB/T13772.2 (Equivalent to ISO13936.2)

GB/T13773.1(Equivalent to ISO13935.1)

GB/T13773.1(Equivalent to ISO13935.2)

GB/T19976; GB 8688; JIS L1096

FZ/T80007.1; FZ/T20019; FZ/T70006; FZ/T70007

ISO 13936-3, 13937-3, 13937-4, 1421, 2411, 2062, 4674-1, 5082, 9073.3, 9073.4, 9073.18

ASTM D5034; ASTM D5035; ASTM D2261; ASTM D5587; ASTM D4964; ASTM D3936; ASTM D1683, D 434, D751, D885 , D2256, D2724, D2731, D3787, D4034, D5733, D5735, etc.

BS 2543, 2576, 3320, 3424, 4303 , 4304,

M&S P11, P12, P13, P14

JIS L1096

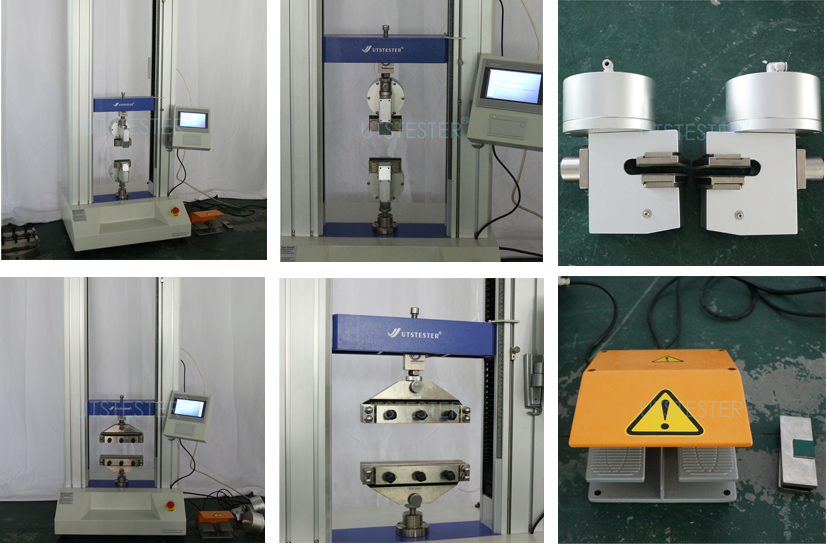

Demonstration

Key Specification

|

Model

|

M001-1

|

M001-2

|

|

Stroke Space

|

1100mm(exclude clamps)

|

900mm(exclude clamps)

|

|

Max. Capacity

|

500N 1000N 2500N 5000N 10000N

|

|

Test Method

|

CRE Principle (Constant Rate of Elongation)

|

|

Display Mode

|

Computer Display Mode

|

|

Sample clamp mode

|

Manual , pneumatic clamp

|

|

Effective collective frequency

|

1000 times/ second

|

|

Resolution of Force

|

1/100,000

|

|

Accuracy of Force

|

≤±0.2% F· S

|

|

Resolution of Stroke

|

0.001 mm

|

|

Test Speed Range

|

0.001-1000mm/min Digit speed control, error ≦±1%

|

|

Gantry Structure Width

|

400mm

|

|

Stop Mode

|

Overload Stop, Emergency Stop Button, Specimen Damage Automatic Stop, Upper & Lower Limit Set Automatic Stop, Automatic Return Function

|

|

Protection measures

|

a. Beam’s upper and lower limit protective device

b. Clamp defend touch protective device

c. Displacement set up & load limit software protective device

d. Sensor overload protection

e. Sample load software protection

f. Overcurrent & overvoltage protection

g. Real time monitor for main parts.

|

|

Machine Drive

|

Servo Motor Drive, Synchronous Wheel and Precision Ball Screw Drive

|

|

Connection

|

Available to connect with pad, WIFI or cellphone to control instrument

|

|

Power Supply

|

AC 220V 50/60HZ 10A

|

|

Dimensions(WxDxH)

|

820x630x1800mm

|

|

Weight

|

120kg

|

Accessory

|

Standard accessories

|

Manual Grips

|

1pc

|

|

English Operation Software

|

1pc

|

|

Cable Connect with PC

|

1pc

|

|

Load Cell

|

1pc

|

|

Optional accessories

|

Desk Top Computer

|

Optional

|

|

Pneumatic Grip

|

Optional

|

|

Other Grips and Load Cell

|

Optional

|

Materials To Be Tested

FAQ

Q1. Can we extract data to PC (without the need for an additional software) and we can print the results directly from the machine.

A1. Extract data to PC should be on basis of software. And the Simple test results can be printed out from machine. But the detailed test results including test curve should be printed out by software on computer.

Q2. Is the software is capable of showing real time progress of the test via a stress strain chart.

A2. Yes. The software is capable of showing real time progress of test via a stress strain chart.

Q3. Is An extensometer included in your quotation.

A3. Extensometer is optional accessory which depends on the specified materials tested.

Q4. I am looking for a machine which will test textile fabrics with a facility of checking the tensile strength, seam slippage and seam strength. I like to test ASTM D 434 and ASTM D 5034 .

A4. M002A with 2.5kg load cell will be right equipment for reference. ASTM D 434 and ASTM D 5034 are the regular tests for textiles quality control.

Q5. When we will select the test method it will automatically directs . Like that whether your machine is having the provision to perform the test .

A5. Yes, sure. This equipment is automatic configuration.

+86 152 6060 5085

+86 152 6060 5085 +86 152 6060 5085

+86 152 6060 5085