+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

Fabric waterproofness is a special requirement for clothing performance and can be categorized into two main categories: waterproofness and impermeability.

I. Waterproofing

Waterproofing is correctly termed "water repellency." A common method involves adding a hydrophobic compound additive to a liquid tank at the entrance of the finishing machine. The fabric is then fed into the tank, padded, and dried, depositing the hydrophobic compound on the fiber surface. The hydrophobic compound modifies the surface tension of the fibers, limiting their reactivity and reducing the attraction of water molecules to the fibers (fiber surface tension is less than the cohesive force of water molecules). Water forms rolling droplets on the fabric surface (much like a lotus leaf pushing dewdrops). This is also known as "water repellency" or "waterproofing" (abbreviated W/R). See the figure below:

Fabric pores allow air and water vapor to pass through, but if water remains trapped in these pores for extended periods or under pressure, it can still penetrate and even absorb moisture. When wearing waterproof clothing in the rain, water droplets will roll off or shake off, but whether the inner layer of the garment or any undergarments becomes damp depends on the amount of rain and the duration of exposure. The surface water-repellent effect of clothing gradually diminishes with washing and prolonged use, eventually becoming ineffective. Therefore, water repellency essentially reduces the fabric's ability to absorb water; it's not truly waterproof, but simply labeled "waterproof."

II. Waterproofing

Waterproofing is truly waterproof. "Waterproof" means resisting or preventing water penetration, which means it's truly waterproof.

True waterproof fabrics are superior to waterproof fabrics. Their physical and chemical properties are relatively stable and generally withstand washing and long-term use. True waterproofing creates an impermeable barrier on one side of the fabric, requiring a high water pressure rating, such as 3000mm or higher. Waterproofing typically involves applying a rubber-based layer or film to the reverse side of the fabric to prevent water penetration. Common methods include coating and lamination.Coating involves applying a fabric coating adhesive or film to one side of the fabric, creating a waterproof membrane. Common methods include direct coating (dry, wet, or hot melt) and transfer coating. Lamination typically involves pressing a layer of waterproof membrane material (commonly known as a "waterproof membrane") onto the fabric to form a single layer. Regardless of whether the fabric is waterproof or not, the membrane adhered to the fabric always acts as a barrier to water penetration. Another lamination method, hot melt calendering, bonds a polymer waterproof membrane to the fabric, achieving the same barrier effect.True waterproofness (or water penetration) is measured and evaluated by resistance to water pressure, measured in millimeters of water column. Using a fixed surface area of waterproof fabric, water is prevented from penetrating from one contact surface to the other. As water pressure increases, the pressure corresponding to the third drop of water penetrating from the surface is the fabric's resistance to water pressure. Generally speaking, fabrics that withstand a water pressure exceeding 1000 mm are considered to have basic waterproofing.

III. Fabric Waterproofing Test

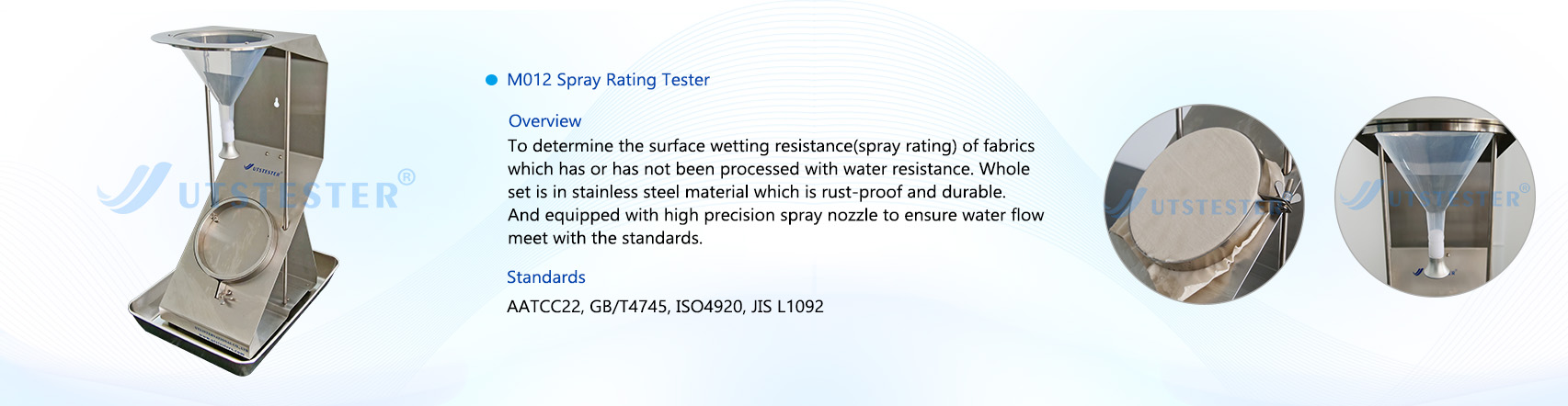

1. Spray Method: AATCC 22-2025 Waterproofness Test

Test Procedure: Under specified conditions and procedures, water is sprayed onto a stretched specimen to form a wet streak on the surface. The size of the wet streak correlates to the fabric's water repellency. The evaluation result is determined by comparing this wet streak with a standard wet streak.

The spray method evaluates the water repellency of fabrics by continuously spraying or dripping water onto the specimen. After a specified period of time, the surface water stain characteristics of the specimen are observed and compared with photographs of specimens at different levels of wetting. The spray method simulates the degree of wetting experienced by clothing in light rain.

This method is applicable to all waterproof and non-waterproof fabrics. The measured waterproof performance results are closely related to the fiber, yarn, fabric treatment and fabric structure. It is usually measured using a spray-type waterproof tester. In the AATCC 22-2005 test method, the test sample is fixed with an iron ring. The sample is kept taut and the surface is flat and wrinkle-free. Distilled water is sprayed from a standard nozzle at a 45-degree angle, aimed at the sample below the nozzle, for 25-30 seconds. The bottom of the iron ring holding the sample is tapped once on a solid object with the test surface facing the solid object. The iron ring is then rotated 180° and tapped again. The sprayed sample surface is then compared with the standard chart and scored to evaluate the waterproof performance of the fabric.

The rating scale is 5, with 5 being the best and 1 being the worst. Level 5: No water droplets on the specimen surface; Level 4: Slightly wet spots on the specimen surface; Level 3: Obvious raindrops on the specimen surface; Level 2: Partially wet specimen surface; Level 1: Completely wet specimen surface.

2. Hydrostatic Pressure Test: AATCC 127-2003 Water Resistance: Hydrostatic Pressure Test

Test Procedure: Apply water pressure to one side of the specimen at a steadily increasing rate until three water penetrations are observed on the other side. Water pressure can be applied from the top or bottom of the specimen. Hydrostatic Pressure Tester

Hydrostatic Head Tester

The hydrostatic pressure test measures the water permeability of a fabric under a certain water pressure. This test is suitable for all types of fabrics, including those with water-repellent treatments.

A fabric's water repellency is related to the water resistance of the fibers, yarns, and fabric structure, and differs from the results obtained when water is sprayed or rained on the fabric surface. There are two methods for measuring fabric water repellency: static pressure and dynamic pressure. The static pressure method applies hydrostatic pressure to one side of the fabric and measures the amount of water released under this pressure, the time it takes for the water to drip off, and the hydrostatic pressure at a given water release rate. Hydrostatic pressure can be expressed as the height of a water column or pressure. In actual testing, water permeability per unit area and per unit time (mL/cm²·h) is measured.For waterproof fabrics, the time it takes for a water drop to appear on the other side of the sample is measured, or the number of water drops that appear on the other side after a certain period of time is observed. In the AATCC 127-2003 test method, at least three samples measuring 200 mm x 200 mm are taken diagonally from the sample to be tested. The two sides of the sample are marked with different water resistance levels. The test is conducted using distilled water at (21 ± 2)°C over a test area of 100 cm². The test surface is immersed in water, and the water pressure is increased at a rate of 60 mbar/min (or 10 mm/s).The test is terminated if water droplets appear at three different locations on the sample. However, water droplets appearing within 3 mm of the sample holder are invalid. The test result is the average of three test samples tested under the same conditions. The higher the test value, the greater the pressure required for water to seep out of the sample, indicating better water resistance.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com