+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

The salt spray test is an environmental test that uses salt spray test equipment to create artificially simulated salt spray environmental conditions to confirm the corrosion resistance of a product or metal material. The severity of the test depends on the duration of exposure.

Laboratory simulated salt spray can be divided into three categories: neutral salt spray test, acetate spray test, copper salt accelerated acetate spray test.

(1) Neutral salt spray test (NSS test) is the earliest emergence of the most widely used in the field of accelerated corrosion test method. It uses 5% of sodium chloride brine solution, solution pH adjusted in the neutral range (6.5 ~ 7.2) as a spray with the solution. Test temperature are taken 35 ℃, the required settlement rate of salt spray in 1 ~ 2ml / 80cm / h.

(2) Acetate fog test (ASS test) is developed on the basis of the neutral salt spray test. It is in 5% sodium chloride solution with some glacial acetic acid, so that the solution PH value down to about 3, the solution becomes acidic, the final formation of salt spray also from neutral salt spray into acidic. Its corrosion rate is about 3 times faster than the NSS test.

(3) Copper salt accelerated acetate fog test (CASS test) is a newly developed foreign rapid salt spray corrosion test, the test temperature of 50 ℃, the salt solution with a small amount of copper salt - copper chloride, strongly induced corrosion. Its corrosion rate is about 8 times that of the NSS test.

(4) Alternating salt spray test

Alternating salt spray test is a comprehensive salt spray test, which is actually a neutral salt spray test plus constant humidity and heat test. It is mainly used for cavity-type whole products, through the penetration of the tidal environment, so that salt spray corrosion is not only produced on the surface of the product, but also inside the product. It is the product in the salt spray and humidity and heat two environmental conditions alternately converted, the final assessment of the electrical and mechanical properties of the whole product has no change.

Special Reminder Before Selection

With the increase in demand for salt spray test equipment market, the production of salt spray test equipment manufacturers are more and more, so the threshold for the production of equipment is not high, there are one or two technicians to find a few dozen square feet of the site can be produced. A penny for a penny, we all know the truth. (Here the good and bad products do not refer to product quality alone, there is a layer of meaning is to be able to reach the national standard of salt spray test)

With the good and bad products, of course, the test results also have a difference. Some customers ask why they do the salt spray test, with same condition of time and brine concentration spray volume with their own suppliers or customers, why they do not corrode and without white spots.

The impact of salt spray test results for several reasons:

1. Time (the longer the corrosion will be more serious.)

2. Brine concentration (the higher the concentration of corrosion will be more serious, the conventional standard concentration of 5%, except for non-standard.)

3. Spray volume is also called the amount of precipitation (the greater the amount of fog corrosion will be more serious, the conventional standard of 1-2ml per hour, at least 16 hours to seek the average, military standards for 3ml per hour.)

4. Temperature (the higher the temperature corrosion will be more serious, to ensure that the display temperature and the actual temperature error within the normal range, so the equipment required to find a third party to measure once a year.)

5. PH value (also known as pH, neutral salt spray test PH value of 6.5-7.2, acidic salt spray test PH value: 3.0-3.2) the last one is the most critical, because the previous items can be regulated by the testers, only this one non-professionals are unable to distinguish whether they can meet the standard.

6. Saturated air barrel aka pressure barrel is really to compressed air heating and humidification, I believe that many people, including those who have used salt spray test equipment for several years, do not necessarily understand what this saturated air barrel is to do, because this part is installed in the electrical control box inside many people do not know what it looks like. In fact, this part is a core component of the salt spray tester, remind everyone not to have on the line, to see if there is a standard design.

Saturated air barrel is used to heat and humidify the compressed air, the requirement is that the compressed air must first pass through the bottom of the saturated air barrel, from the bottom of the heated water through the room temperature compressed air heating and humidification to the specified temperature, neutral salt spray test saturated air barrel temperature of 47 degrees, acid salt spray test for 63 degrees, note that this temperature is not the temperature of water but air temperature.) The standard material for making is 304 stainless steel plate. But the aforementioned due to price competition many plastic materials, do a fake barrel can only be filled with water heating can not enter the air so you can see the temperature rise. Not a professional look at the appearance of what can not see the door. Because the plastic bucket a pressure is easy to burst they simply not into the air. There are also stainless steel to do air pressure after the pressure barrel but not after the bottom of the water, just from the top of a mouth to enter from another mouth and out, so with no air almost, because this is not to compressed air heating and humidification.

How to distinguish whether there is no real underwater heating and humidification it? Teach you a method is very simple to listen to hear out, as long as the spray work carefully listen to the inside of the electrical box can be heard like boiling water or like a pipe from the bottom of the cup filled with water blowing poof sound, that means that this is in line with the standard salt spray test machine.

We do not to suggest that user to buy the more expensive the better, just do not hopeto buy a device that does not meet the test requirements. Because only look at the appearance of the equipment are similar. Convenient to visit the examination before buying. Whether we can work together, UTSTESTER instruments are very willing to provide technical assistance to you.

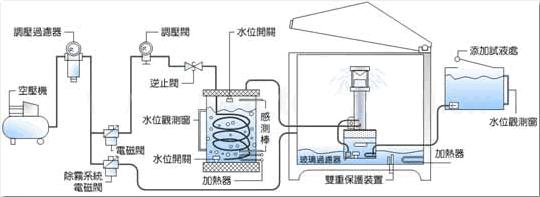

Salt spray tester working principle diagram

Know more about the Salt Spray Tester ,plesae click here.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com