+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

In real life, often encounter clothing products in the process of wearing or care of the phenomenon of pilling and pilling, which seriously affects the appearance of clothing, not only to consumers caused trouble, but also affect the credibility of the business. Therefore, the pilling performance is one of the important indicators to examine the quality of clothing. That a beautiful clothes, why will pilling?

First, let's understand the process of pilling. When the fabric in the process and use of external friction, such as friction is greater than the fiber strength or friction between the fibers or holding force, the fiber end will be pulled out of the formation of rings and fluff, the fabric surface generated fluff and make the fabric surface lose luster. When the lint reveals a certain length, the lint between a certain distance due to rubbing friction, repeated elongation and retraction and entanglement into a ball, due to different fiber breaking strength, yarn twist, fabric structure and other differences, some lint ball formation is very easy to fall off, while some are not easy to fall off, entangled with each other, plus easy to hide dirt, seriously affect the beauty of clothing.

GB/T4802.1-2008 "Determination of fabric pilling performance Part 1 round track method".

1 Application range

Mainly applied in China, few foreign countries use this method. It is mainly applied to woven fabrics (such as jackets, shirts, dresses, etc.), woolen fabrics (such as coats, suits, pants, etc.) and some knitted fabrics (such as school uniforms, sportswear, T-shirts, underwear, etc.).

2 Testing principle

According to the specified method and test parameters, using nylon brush and fabric abrasives or fabric abrasives only, so that the specimen rubbing hair pilling. Then, under the specified lighting conditions, the visual description of the pilling performance is evaluated.

3 Equipment

(1)Round track pilling instrument

The specimen jig and the grinding table make relative vertical movement. Its dynamic range is (40±1) mm, the trajectory of the relative movement of the sample holder and the grinding table is a circle of diameter (40±1) mm, the relative movement speed is (60±1) r/min, the inner diameter of the sample holder is (90±0.5) mm, and the holder can exert the specified pressure on the sample.

(2)Test operation

1. Humidification and test atmosphere using the temperature (20±2)℃, relative humidity (65±4)% of the standard atmosphere, humidification at least 16h.

2. From the sample cut 5 diameter (113 ± 0.5) mm round specimens, in the reverse side of each specimen well marked, and cut another piece of rating required to compare the sample.

3. Check the instrument, nylon brush before the test, and install the foam spacer, specimen and fabric abrasive on the test chuck and abrasive table respectively, with the specimen facing outward.

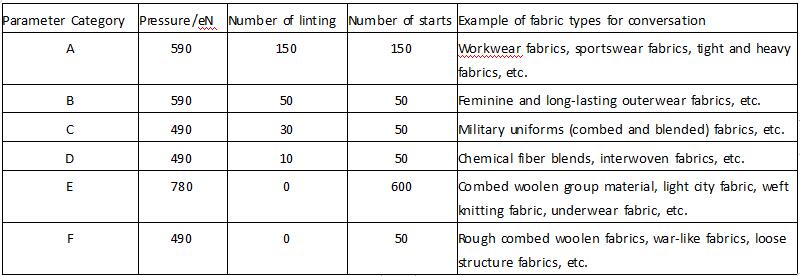

Table 1 Test parameters and examples of applicable fabric types

4.Rating

In the darkroom, a measured sample and an unmeasured sample are placed side by side in the middle of the rating box specimen plate along the longitudinal direction of the fabric, with the measured sample on the left and the unmeasured sample on the right.

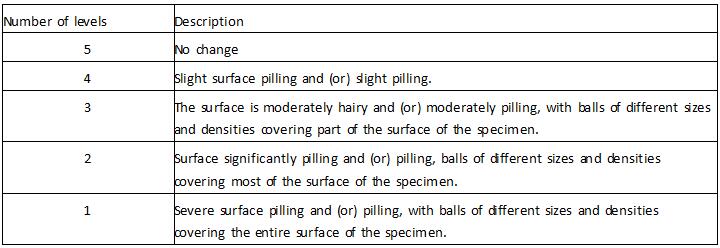

At least two people grade each specimen according to the visual description in the table below, and if it is between two grades, record a half grade, e.g. 3.5.

5.Results

Sample test results are the average of all personnel ratings, if the average is not a whole number, modified to the nearest 0.5 level and use "-", such as "3-4", if the difference between individual test results and the average is more than half a level, then each piece of specimen should be reported at the same time The number of levels.

Know more about the Pilling Tester ,plesae click here.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com