+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

Seam slip is a fabric problem, especially for fabrics that contain smooth yarns or have an open structure or a low number of warp and weft interweaves.These factors mean that one set of yarns can easily pass through another set of yarns.Seam slippage is the condition under which seams sewn in a fabric are opened under load.Some of these gaps may close when the load is removed, but some of them may be permanently deformed.

Fabric seam slip test

Joint slip test:

Fabric seam slip tester is used to determine the resistance to slip of warp or warp filled yarns using a standard seam.

There are three different types of seam slip tests, each with its own disadvantages.The first is the type of joint where the standard joint is placed under a fixed load and the joint clearance is measured.In the second type, a load extension curve is drawn with and without a standard joint and the difference between the two curves is treated as a sliding point.The third type does not require stitching and measures the force required to move a set of needles through the fabric.The first type of variation is to measure the load required to give a fixed joint opening.

Joint slip test procedure:

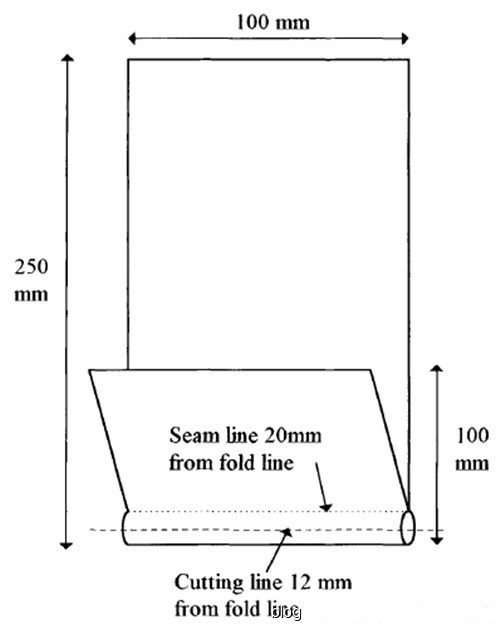

The British standard joint slip test is for the second type of test.Use five warp and five weft samples, 100mm x 350mm each.Each sample is folded 100mm from one end and stitched 20mm from the fold using the special sewing thread and sewing machine Settings detailed in the standard.The layout of the sample is shown in the figure.After sewing, cut the folded part of the fabric 12mm from the fold line and 8mm away from the cut edge.Use a standard strength tester equipped with a 25mm grab test jaw. The gauge length is set at 75mm.

Before testing, the sample is cut into two parts, one with a seam and one without, but each part contains the same warp or weft.Firstly, stretch the sample without joints to the load of 20ON in the tensile testing machine and draw the force elongation curve.The matched samples with the seams are then tested in the same manner to ensure that the force elongation curve starts at the same zero position.

To find the force required to open the seam a certain distance, measure the curve separation of 5N forces and add the distance to the specified seam opening (usually 6mm but some specifications require 5mm) to allow the horizontal scale of the chart.Next locate the point on the curve that is separated from the distance and read the load value at that point from the chart.If the curve does not reach the specified interval below 20ON, the result is recorded as "over 20ON."

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com