+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

Fabric downproof testing machine refers to the performance of fabric to prevent the leakage of down or feather from the crack of yarn. Denotes the number of drill roots under specified conditions.

Suitable for testing the anti-drilling properties of the lining and fabrics used in making down products.

Test Method

The sample is made into a bag with a certain quality of down. It is placed in the turning box of the tester, and the hard rubber ball is also loaded in the turning box. The rotating box rotates at a certain speed, drops the rubber ball with a certain height, and impacts the sample to simulate various squeezing, rolling and collision of down products in the process of taking. The anti-drilling properties of the fabric were assessed by counting the number of down roots drilled from inside the sample.

Standards

FTMS 191-5530, GB/T12705.2

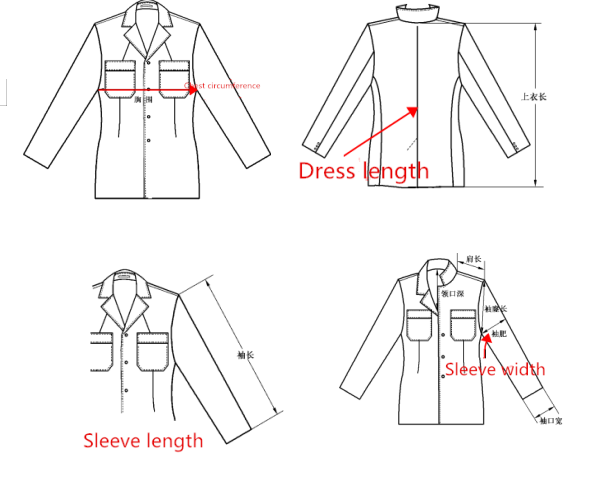

1 According to GB/T 31907, measure the garment length (or pants length, skirt length), bust (or waist circumference), sleeve length, and sleeve fatness of the sample; the length of the hem, cuffs, waist, etc. that are not filled with down is not included. When the hood of the down jacket is filled with down, measure the maximum width and maximum height of the cap after the cap is folded in half longitudinally and flattened (as shown in the figure below).

2. Clean the hair, down and velvet inside and outside the test rotary box, and wipe off the silicone rubber special-shaped ball.

3 Pull up the zipper of the garment before the test to keep it in use. If there is a fur collar, it should be removed. If appropriate, the fur collar suture should be glued and sealed with glue to prevent the down from coming out. Carefully remove the exposed feathers, down and down silk on the inner and outer surfaces of the tested sample, and then carry out the test. If the length of the garment is too long, the sample can be folded in half and put in horizontally.

4 The number of revolutions of the preset counter is 1440 times, press the forward start button, and the rotary box starts to rotate.

5. After the automatic stop at full count, take out the tested sample slowly to prevent the feathers, down or velvet on the surface of the sample from falling off and affect the test results. Carefully check and count the number of feathers, down or down filaments drilled out with a length ≥ 2mm.

6 Calculation of test results

6.1. The total relative area of the sample is the sum of the relative areas of the inner and outer surfaces of the down garment. See the formula for calculation. The relative area of parts not filled with down and double counted parts is not counted. According to GB/T 8170, the test results are rounded to 0.01.

Relative area of the sample (㎡) = (2 clothing length X bust + 8 sleeve length X sleeve fat + 4 maximum width after the hat is folded vertically in half X maximum height after the hat is folded vertically in half)

Specimen relative area (St) = (2L1XL2+8L3XL4+4L5XL6) X10^(-4)

St---the relative area of the sample, in square meters (㎡)

L1---clothes length (or trousers, skirt length), in centimeters (cm)

L2---bust (or waist), calculated around the circumference, in centimeters (cm)

L3---sleeve length, in centimeters (cm)

L4---sleeve fat, calculated by width, in centimeters (cm)

L5---The maximum width of the hat after being folded in half longitudinally, in centimeters (cm)

L6---The maximum height of the hat after being folded in half longitudinally, in centimeters (cm)

6.2. See the formula for the calculation of the drill down value of the sample. The test results are rounded to integers according to GB/T 8170.

Drilling wool value of sample (root/㎡) = total number of drilling wool of the sample (root)/relative area of the sample (㎡)

When the drill down value exceeds 200/m², the test result records "greater than 200/m².

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com