+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

As people's lifestyles become more and more healthy, physical fitness activities are widely carried out. After exercising, in addition to enjoying the happiness brought by exercise, a lot of sweating also makes the body feel very uncomfortable for a long time. In order to improve the physical discomfort after exercise, you can choose to wear products with moisture absorption and quick-drying properties when exercising.

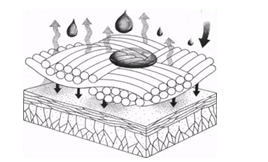

What is moisture absorption and quick drying performance? Moisture absorption and quick drying means that when the human body produces a lot of sweat after strenuous exercise, it can quickly absorb sweat and conduct it to the outer surface of the fabric for rapid volatilization, keeping the body dry and comfortable.

What is the mechanism of the moisture absorption and quick drying function? Normal people emit heat from the body due to metabolism through respiration, skin conduction, convection, radiation, and sweat evaporation. Strenuous exercise or high ambient temperature, such as above 30°C, the temperature difference between the environment and the human body is small, and sweating and evaporation become the main form of body temperature regulation. The liquid moisture secreted and flowed out from the skin surface is first absorbed by the fiber material, and at the same time, the capillary effect produced by the voids (micropores, capillary pores, etc.) inside the fiber and the gaps between the fibers makes the moisture adsorb and diffuse in the material. . The results of these two effects lead to the migration of water. The moisture absorption is mainly related to the chemical structure of the fiber macromolecules. The hydrophilic groups of the fiber macromolecules make the water molecules lose the ability of thermal movement and remain in the fibers. Adsorption and diffusion are related to the physical structure of the fiber, and water molecules are easy to diffuse in areas with rough morphology, micropores or voids. The same is true for the drying process. After moisture is absorbed by the fiber material, it is released from the surface of the material.

After knowing the mechanism of moisture absorption and quick-drying, introduce the moisture absorption and quick-drying test standard GB/T21655.2-2019 "Assessment of moisture absorption and quick-drying properties of textiles Part II: Dynamic moisture transfer method"

The equipment used in this test is a liquid water dynamic transmission performance tester. The principle is that the fabric sample is placed horizontally. After the test liquid contacts the water-immersed surface, the liquid water will diffuse along the water-soaked surface of the fabric and transfer from the water-soaked surface of the fabric to the permeable surface. , while diffusing on the permeable side of the fabric, the water content change process is a function of time. When the test liquid is dripped into the water-immersed surface of the sample, the dynamic transfer of liquid water is measured using the sensor in close contact with the sample, and a series of performance indicators are calculated to evaluate the moisture absorption, quick-drying and moisture-wicking properties of the textile.

After all the samples are debugged according to the standard, the test can be started:

1. Use clean tweezers to pick up a corner of the sample to be tested, take the side of the sample close to the body as the water immersion surface, and place it flatly between the two sensors of the instrument facing the direction of the test liquid drop.

2. Start the instrument, drop (0.22±0.01) g test solution into the water-immersed surface of the fabric within the specified time, and start recording the time and water content changes. From the beginning of dropping the test solution to the end of the test, the test time is 120s , The data collection frequency is not lower than 10Hz.

3. Take out the sample, absorb the excess residual liquid on the sensor plate with clean absorbent paper, let it stand for at least 60s, and make sure that there is no residual liquid before testing again. Test the remaining samples as described above.

The results are soaking time, water absorption rate, maximum wetting radius, liquid water diffusion rate and one-way transmission index, and the average value of each index is calculated, and graded according to the standard index classification.

Rating

|

Rating according to Table 1. |

|||||

|

Table 1 Performance indicator levels |

|||||

|

Performance index |

Level 1 |

Level 2 |

Level 3 |

Level 4 |

Level 5 |

|

Wetting time T/s |

>120.0 |

20.1~120.0 |

6.1~20.0 |

3.1~6.0 |

≤3.0 |

|

Water absorption rate A/(%/s) |

0~10.0 |

10.1~30.0 |

30.1~50.0 |

50.1~100.0 |

>100.0 |

|

Maximum soaking radius R/mm |

0~7.0 |

7.1~12.0 |

12.1~17.0 |

17.1~22.0 |

>22.0 |

|

Liquid water diffusion velocity S/(mm/s) |

0~1.0 |

1.1~2.0 |

2.1~3.0 |

3.1~4.0 |

>4.0 |

|

One-way transfer index O |

<-50.0 |

—50.0~100.0 |

100.1~200.0 |

200.1~300.0 |

>300.0 |

|

Note: The submerged water surface and the permeable surface are graded separately, and the grading requirements are the same; Level 5 is the best and level 1 the worst. |

|||||

When the corresponding performance of the product before washing and after washing meets the technical requirements for performance evaluation, it can be evaluated as having moisture absorption and quick-drying and/or moisture absorption and sweat-wicking properties.

|

Table 2 Technical requirements for performance evaluation |

||

|

performance |

entry |

required |

|

Moisture absorption and quick drying |

Soaking time * |

≥Lv 3 |

|

Water absorption rate * |

≥Lv 3 |

|

|

Maximum soaking radius of penetration surface |

≥Lv 3 |

|

|

Diffusion velocity of liquid water at the permeable surface |

≥Lv 3 |

|

|

Hygroscopic and perspirant |

Wetting time of penetration surface |

≥Lv 3 |

|

Water absorption rate of penetration surface |

≥Lv 3 |

|

|

Unidirectional transfer index |

≥Lv 3 |

|

|

Both the water level and the penetration level should be reached. |

||

Identification

Products tested and identified in accordance with this section with the corresponding functions in Table 2 shall be marked on the instructions for use:

- The number of this part, i.e. GB/T 21655.2-2019;

- The corresponding performance of the product, such as moisture absorption and quick drying or moisture absorption and perspiration.

When the corresponding performance of the product before washing and after washing meets the technical requirements for performance evaluation, it can be evaluated as having moisture absorption and quick-drying and/or moisture absorption and sweat-wicking properties.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com