+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

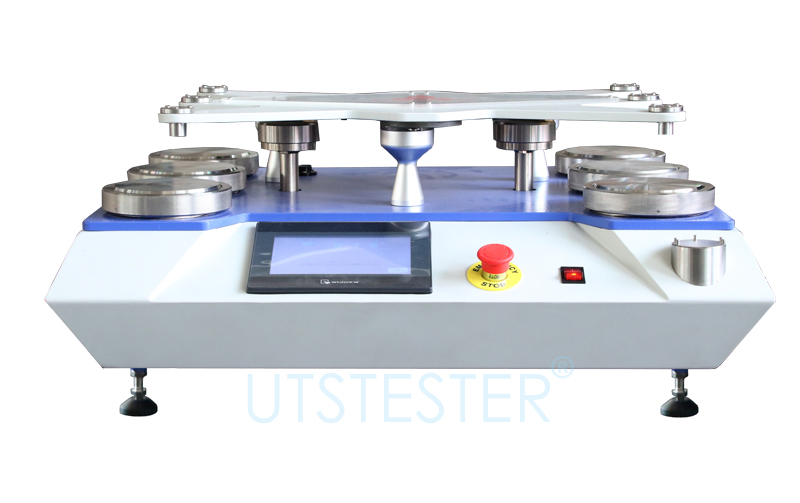

Martindale wear resistance and fuzz tester features:

1. Industrial color touch screen display, control, friendly man-machine interface is easy to use, easy to operate.Chinese and English display is convertible.

2. Each station counts separately, the number of revolutions can be set in stages, and the process bar graph shows the test process.It has automatic warning function of abrasive life.

3. The test stage (a total of 8 levels) and the number of tests in each stage can be programmed, and a single program can be repeated to adapt to various test requirements.

4. Brushless DC motor control technology, speed digital setting can also set three speeds, can meet the standard.

5. It has the function of automatically restoring to working state after power failure, that is, it can automatically start running until the test is completed after power failure.

6. The main parts are made of aluminum alloy, the surface is treated by plastic spraying and sandblasting oxidation.Motion guide rail is made of stainless steel, durable, eccentric adjustment adopts cylindrical pin plug type structure, easy to operate, each grinding head has a number.

Martindale wear resistance and fuzz tester operation method:

1. Sample preparation.In standard environment, tiled, no stretching state according to different standards for a period of time.

2. Sample selection.Cut a sample from different parts of the whole fabric, the sample should be representative.If it is a fancy fabric, the sample should include all the different textures and colors of the fabric;

3. Remove the load and load shaft from the test machine;

4. Remove the top plate and test fixture;

5. Sample device: loosen the fixing ring on the test fixture, take down the sample press, and put the sample into the base of the test fixture.When the tested fabric is not more than 500g/m2, a piece of polyester foam is placed between the sample and the metal plug of the sample holder.More than 500g/m2, or composite fabric, do not need to pad foam.The specimen on each specimen holder shall be subjected to the same tension.

6. Wool felt and friction cloth device: put the felt and abrasive on the grinding table, put the heavy on the abrasive, and then put the pressure ring, screw the nut, so that the pressure ring fixed the abrasive on the grinding table.

7. Put the grinding head on the abrasive to pressure;

8. Place the test fixture with the sample face down on the base fixture, adjust the circular groove of the test fixture to align with the load shaft rod, so that the load shaft rod is inserted into the circular groove of the test fixture;

9. According to the standard setting times, start the switch, start the test, automatically stop after reaching the set times:

10. Remove the sample and compare the standard sample in the rating box.

Email: hello@utstesters.com

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com