+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

2021-05-17

We usually wear sweaters elbow is particularly easy to deformation, knit pants knee is the first to wear holes, not to mention the socks from time to time there are toes drill out to observe the world, consumers will often question, these situations is the quality of the fabric?Or is it the fabric itself?In fact, these issues boil down to the durability of the fabric.

As one of the testing items of textile mechanical properties, strength testing plays a key role in evaluating the durability of fabrics.At present, the strength of knitted fabrics and non-woven fabrics is assessed by bulging property or breaking property.So, how was this performance tested?For what products?What are the test steps?What are the requirements for the inspectors?

1. What is the principle of the textile bursting test and top breaking test?What are the test methods and corresponding standards at home and abroad?

The principle of bursting strength is that the sample is clamped in the ring sample clamp of the fixed base, and the spherical jacking rod is vertically jacked to the sample at a constant moving speed, so that the sample is deformed until the rupture, and the bursting strength is measured.

The principle of bulging test is to clamp the sample on an extensible diaphragm, apply liquid pressure under the diaphragm, and increase the volume of the liquid at a constant speed, so that the diaphragm and the sample expand until the sample rupture is measured bulging strength and dilatancy.

There are mainly 3 domestic and foreign test standards for breaking strength commonly used: GB/ T19976-2005 "steel ball method for determination of breaking strength of textiles";ISO3303-1:2012 "Determination of breaking strength of rubber - or plastic-coated fabrics - Part 1: Steel ball method";GB/T 8878 -- 2002 "cotton knitted underwear" 5.4.1.

The commonly used domestic and foreign standards for the bursting test mainly include: GB/T 7742.1 -- 2005 "Textiles and Fabrics Bulging Properties -- Part 1: Determination of Bulging Strength and Bulging Expansion", GB/T 7742.2 -- 2015 "Textiles and Fabrics Bulging Properties -- Part 2:Determination of bursting strength and expansion of bursting pressure method, ASTM D3786/D3786M -- 2018 "textile bursting strength test method diaphragm method", ISO 13938 -- 1:2019 "textile fabric bursting properties part 1:Determination of bursting strength and dilatancy, hydraulic method, ISO 13938-2:2019, "Textiles and fabrics bursting properties - Part 2: Determination of bursting strength and dilatancy by pressure method"

2. What are the similarities and differences between the two assessment indicators?

The common principle of the two assessment indexes is that circular stress is applied to the flat fabric at a certain speed in the vertical direction to deform the fabric and cause the fabric to burst.The main difference is that the bursting force is a spherical jacking rod directly and vertically acting on the fabric blasting, and the bursting force is a pressure or hydraulic pressure to push the diaphragm to expand so that the fabric in contact with the deformation of the blasting effect.The numerical unit of bursting strength is Newton N, and the numerical unit of bursting is kPa.

In terms of bulging standards, the difference between the Chinese standard and the American standard ASTM is that there are clear provisions on the medium. The gas and liquid media are divided into two standards, while the American standard ASTM includes both gas and liquid.Another difference is that the GB only tests 5 points, while the US Standard tests 10 points.

3. Within the scope of China's current product standards, which products need to examine this kind of performance?

Within China's current product standards,To assess the top breaking strength of GB/T 22848 -- 2009 "knitted fabric", GB/T 22849 -- 2014 "knitted T-shirt", GB/T 22854 -- 2009 "knitted student clothes", FZ/T 73010 -- 2016 "knitted sweater", FZ/T /T73032 -- 2017 "Knitted Denim Clothing", FZ/T 73056 -- 2016 "Knitted Suit", FZ/T73037 -- 2019 "Knitted Sports Hosiery", FZ/T 73060 -- 2017 "Whole Knitted Vamp" and other dozens of common product standards.

The items to be examined include GB/T 31888 -- 2015 School Uniforms for Primary and Middle School Students (wool knitting), FZ/T 73009 -- 2009 Cashmere Knitwear, FZ/T 73018 -- 2012 Wool Knitwear, FZ/T 62014 -- 2015 Mosquito Nets and FZ/T64017 -- 2011 Needle Compression Elastic Nonwovens, etc.

4. What quality problems can this index performance test reflect about textiles?

This index performance can help enterprises, consumers understand the damage properties of products, especially for knitwear and some nonwovens.Product damage analysis analysis to the performance of single yarn, and of course more micro and meticulous, but if each product to remove the circle, pine yarn end see single yarn, operation process trival, and fabric tensile ductility generally better than woven fabrics, knitted coil structure can also affect consumer to use, so not only by single yarn situation to judge the product performance.It is an intuitive and effective test method to measure the blasting force by directly bursting or bursting to simulate the deformation of knitted fabric driven by elbow, knee, toe and so on.

5. Can you give an example of a specific textile to introduce the procedures of bursting and topping testing?

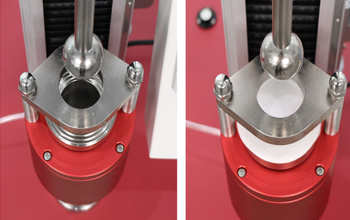

(1) Top breaking strength test method.Take GB/T 19976 -- 2005 as an example, take a piece of humidification after knitting sample for the following steps: ① cut out 5 samples, mark the front and back, placed in GB 6529 atmosphere for humidification.(2) the sample is reversed up and clamped on the gripper to ensure that the sample is flat, no tension and no wrinkle.③ Select the diameter of the steel ball, and install the jacking rod and gripper on the Fabric bursting tester. The jacking rod pushes down the specimen at a rate of 300mm/min (Figure 1).(4) After the test is completed, the force value is recorded, and the remaining 4 samples are tested to calculate the average value.

Picture 1

(2) bursting performance test method.Taking GB/T 7742.1 -- 2005 "Textiles Bulging Properties -- Part 1: Determination of Bulging Strength and Bulging Expansion by Hydraulic Method" as an example, a piece of moisture-adjusted knitted sample was taken, the test area was 7.3cm2, and the test was carried out.

Test steps

① Open the instrument

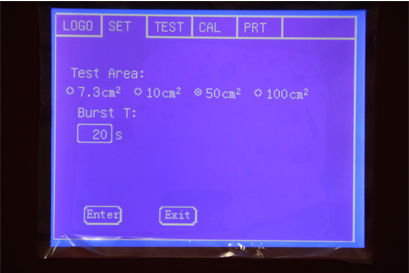

Select the test area of 7.3cm2 and test times of 5 times(Pic.2).

Picture 2

② Open the protective cover of the instrument

Lay the sample face up in the test hole (Pic. 3)

Picture 3: Place the sample

Put down the protective cover, and then put down the test cover, and fix the sample.

③ Open the instrument

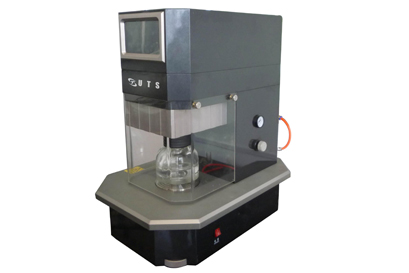

The bursting strength of the first point is measured. If the bursting time is not within the range of (20±5) s, it should be removed. In the follow-up test, the instrument will automatically adjust the flow rate to keep the bursting time within the range of (20±5) s.The sample is removed and tested with an empty machine as described above (Pic. 4). At this time, the "diaphragm pressure" is measured and the instrument automatically deducts the "diaphragm pressure" to obtain the bursting strength of the sample.

Picture 4: Empty engine test

6. What are the difficulties and problems to be paid attention to in the test?

First, the sample should be representative, the test area should avoid folding, wrinkling, and avoid cloth edge.

Secondly, distinguish the positive and negative sides of the sample in accordance with the standard requirements;In general, because the actual wearing process faces outwards, the purpose is to simulate the normal state of human body wearing clothing, and the bulging process is carried out from the bottom to the top, so the reverse side of the sample is facing the diaphragm and the front side is up, which is consistent with the actual wearing state.The sample should also be first in accordance with the standard requirements of humidity adjustment.

Again, for the burst of charged, usually for preliminary experiments, to the control of flow velocity, the subsequent test, instrument according to the preliminary experiments automatically adjust the flow velocity, ensure the burst time within the scope of the (20 + 5) s, in the process of test, the burst time is beyond the scope of (20 + 5) s point, also should give up, test again.If there are multiple points of bulging time is not within the range, it should be timely check whether the instrument failure, whether there is oil leakage, or whether the test cover is loose and other problems.

Finally, the person applying the standard must understand the exact parameters and details of the topping and bulging methods.For the test speed used, pin diameter, ring inner diameter (test area), number of samples, etc., some standards are specified, others need to be negotiated.For example, different test areas and diameters of billiards have obvious effects on numerical results. For example, the diameter of the steel ball used in the standard FZ/T 73037 -- 2019 for socks is 20mm, while the diameter of the steel ball used in the overall forming knitted vuette FZ/T 73060 -- 2017 is 25mm.These two products are different from the standard diameter of 38mm used in general knitting products.The reason is that these two standards are foot wear articles, the use of small diameter steel ball is more in line with the actual use of the state.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com

Previous article :

Performance testing machine for paper productsNext article :

Why does the fabric shrink?