+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

2018-06-19

Yarn for dyeing is more demanding than ordinary bobbins. In particular, it is required that the density of the package yarn is uniform, there is a very precise non-overlapping yarn layer, the spindle length is more accurate, and the unwinding of the yarn is better. This package has superior liquid permeability during the dyeing process.

With the enhancement of people’s aesthetic consciousness and improvement of living standards, high-end yarn-dyed products have become more and more popular. Not only real silk, chemical fiber, rayon, blended yarns, and cotton yarns can also be made of colored yarns, which has prompted the soft color process of yarn drums to be widely used in the yarn-dyed industry. Before dyeing the general bobbin, the purchased blank must be bundled into a “loose bobbin” suitable for bobbin dyeing. This is why the demand for loose precision bobbin winding machines is increasing. How to produce a qualified loose bobbin package to facilitate even dyeing of the bobbin becomes a problem that people need to solve.

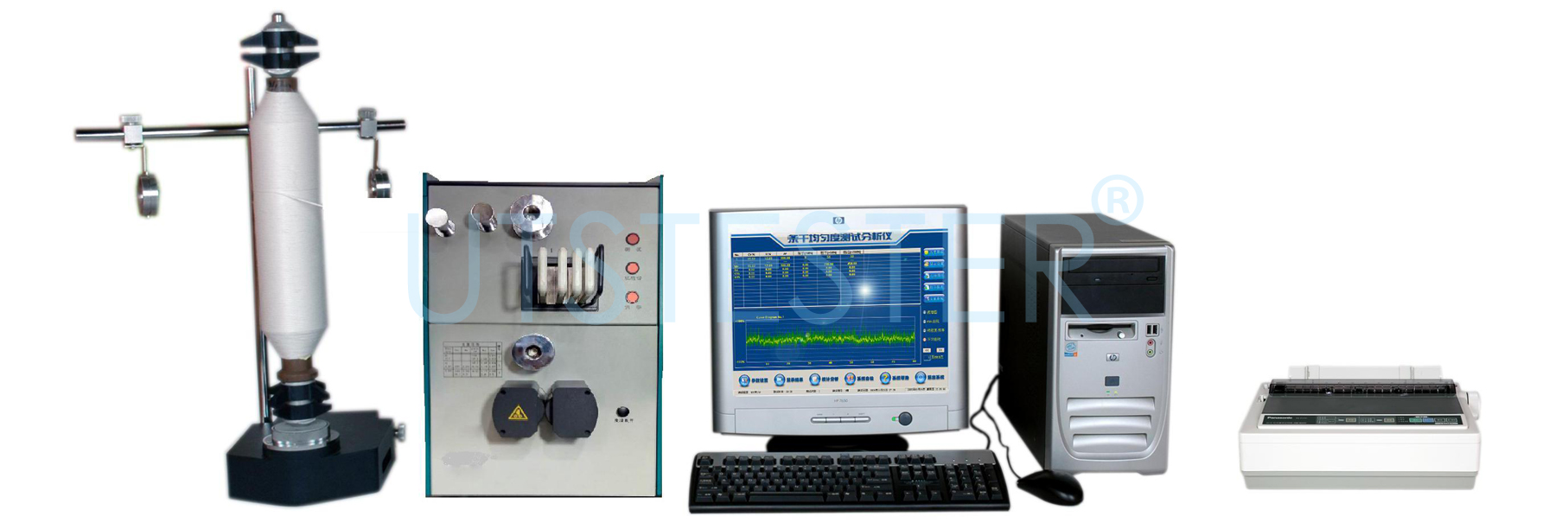

Yarn testing equipment carried on the experimental analysis to the related factors which influence the tube yarn density and the uniformity, has optimized the related craft parameter. The following conclusions have been drawn:

1. Loose winding speed does not affect the drum density;

2. Arm pressure has a greater influence on the density. Generally, when the density difference is large, the adjustment arm pressure is given priority;

3. Tension is a key factor in controlling the yarn density of the bobbin. Fine adjustment occurs when the bobbin yarn density is not much different.

4. The purpose of overfeeding is to fully release the tension, depending on the type of yarn can choose different overfeeding ratio;

5. The intersection angle is mainly used to eliminate hard edges and facilitate the next process unwinding with the soft edge table. Generally, the precision type is selected. Different cross angles can be selected according to the yarn type. Cross angle generally should not choose too much;

6. The temperature and humidity have a great influence on the loose package density, and generally it is required to control its stability.

More information, please contact now:

Web: www.utstesters.com

Email: hello@utstesters.com

Tel: +86-596-7686689

Previous article :

Tensile testing apparatusNext article :

Single yarn tensile strength test