+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

45 Degree Automatic Flammability Tester:Overview

To determine textile damaged area and length at 45 degree condition and the times of touching flame when textile is melted to specified length after heated at 45 degree condition.

Stainless steel test cabinet with glass observation panel provided with automatic timing of flame spread in 0.1 second increments from ignition. Automatic or manual flame impingement for 1,5 or 20 seconds.

Test Principle

Under the specified condition, mount the sample on the U shape holder at 45°, ignite sample in 1 second. The needed time(to make sample burn with flame up to a certain of distance) will be seen as the reference to assess fabric burning intensity. The fabric’s surface with gigging, ignite or melt state for bottom of fabric should be taken as extra index of burning intensity, which need to be marked.

Standards

16 CFR 1610 ASTM D1230 CA TB117 GB/T 14644 JIS L1091

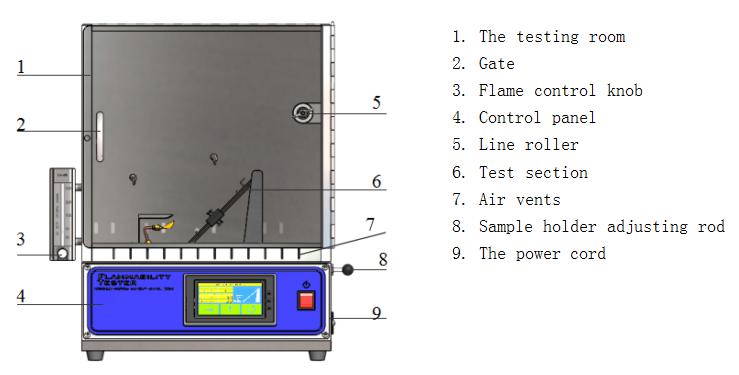

structure

function description:

1. Test room: provide standard space for testing

2. Sliding door: close during the test to prevent the external environment from affecting the test

3. Flame adjusting knob: control the air intake and adjust the flame length. Rotate counterclockwise to increase the flame length and clockwise to reduce the flame length until it is closed

4. Control panel: including control instrument and switch

5. Line roller: the marked cotton thread is wound on the line roller, so that the standard cotton thread can be suspended conveniently. With cotton thread, the line roller can be reused.

6. Test section: for the test section, see figure 2

7. Air vent: control a small amount of air to enter the test room during the test to ensure the flame burning

8. Specimen holder adjusting lever: adjust the position of all the test positions

9. Power cord: supply power to the instrument

Features

1. Test chamber in imported brushed stainless steel with 1.5mm thickness material. Heat-resistant and smoke-resistant, easy for cleaning. Durable and easy maintenance.

2. Free set ignition time, with automatic timing of flame spread in 0.1 second increments from ignition.

3. Brushing Device including Nylon Brush is available per request.

4. Flame height adjustment is controlled by high precision rotor flow meter, which makes flame be stable and easy to be adjusted.

5. Equipped with heat resistant glass observation panel which is convenient for test control.

6. 4.3 inch color touch screen display. Menu type operational mode which is very smart.

7. Core component adopts ST Microelectronics 32 bit multiple function main board to process data.

8. The control panel is made of special aluminum and has a metal key, which is beautiful and not easy to damage.

9. South Korea imported motor and decelerator, make the burner moves smoothly and accurately.

10. The burner in B63 material processed, corrosion-resistant, non-deformed and rust resistance.

11. Automatic ignition(Replace manual ignition type).

12. Auto cut off air supply once ignition time reached. ( Replace manually switch off function).

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com