+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

Nonwovens break through the traditional textile principle, and has a short process, production speed, high yield, low cost, wide use, raw material sources and other characteristics, is a new generation of environmental protection materials, with water-resistant, breathable, flexible, non-combustion-supporting, non-toxic non-irritant, colorful and other characteristics.

Non-woven production fiber is polypropylene (PP), polyester (PET). In addition, there are polyamide fiber (PA), viscose fiber, acrylic fiber, acrylic fiber (HDPE), chlorine fiber (PVC).

According to application requirements: non-woven fabric is divided into disposable application and durable two categories.

According to the production process, it is divided into:

1, spunlaced non-woven fabric: spunlaced process is the high pressure fine water jet to a layer or multi-layer fiber net, so that the fiber tangled together, so that the fiber net can be reinforced and have a certain strength.

2, thermal bonding non-woven fabric: thermal bonding non-woven fabric refers to the addition of fibrous or powdery hot-melt bonding reinforcement material in the fiber net, fiber net after heating melting cooling reinforcement into cloth.

3, pulp air flow into the net non-woven fabric: air flow into the net non-woven fabric can also be called dust-free paper, dry paper non-woven fabric. It is the use of air flow into the net technology of wood pulp fiberboard loose into a single fiber state, and then use air flow method to make the fiber agglutinate on the net curtain, fiber net and then reinforce into cloth.

4, wet non-woven fabric: wet non-woven fabric is placed in the water medium of fiber raw materials loose into a single fiber, at the same time to make different fiber raw materials mixed, made of fiber suspension slurry, suspension slurry transported to the network mechanism, fiber in the wet state into a network and then reinforced into cloth.

5, spunbond non-woven fabric: spunbond non-woven fabric is in the polymer has been extruded and stretched to form a continuous filament, filament laid into a net, fiber net after its own bonding, thermal bonding, chemical bonding or mechanical reinforcement method, so that the fiber net into non-woven fabric.

6, melt-blown non-woven fabric: the process of melt-blown non-woven fabric: polymer feeding - melt extrusion - fiber formation - fiber cooling - mesh - reinforcement into cloth.

7, needle-punched non-woven fabric: needle-punched non-woven fabric is a kind of non-woven dry method, needle-punched non-woven fabric is the use of needle puncture effect, the fluffy fiber net reinforcement into cloth.

8, sewing non-woven fabric: non-woven fabric is a dry non-woven fabric, knitting method is the use of warp knitting coil structure of fiber net, yarn layer, non-textile materials (such as plastic sheets, plastic thin metal foil, etc.) or their combination to reinforce, to make non-woven fabric.

9, hydrophilic non-woven fabric: mainly used in the production of medical and health materials, in order to get a better feel and do not scratch the skin. Like sanitary napkins, sanitary pads is the use of hydrophilic non-woven fabric hydrophilic function.

Features and Uses

Durability, disposable. Insulation, conduction. Softness, stiffness. Fineness and expansibility. Isotropy, anisotropy Filter, breathable and impervious to water. Flexibility, stiffness.

Light, loose, warm. Thin as cicada wings, thick as felt. Waterproof and moisture permeable.

Ironing, stitching, molding. Flame retardant, antistatic. Water permeable, waterproof, wear-resistant and fleece resistant.

Wrinkle resistance, good elasticity, high moisture absorption, water repellent.

Medical and health: surgical gown, cap, hood, plaster cotton, women's sanitary napkin, baby diapers, wet face towel, sanitary underwear, dust cover.

Agriculture: harvest cloth, greenhouse cloth.

Industry: diskette lining, horn cloth, filter material, sound insulation felt, sealing ring lining, cable cloth, FRP reinforced towel, industrial wipe cloth, shockproof gasket, insulation material, tape base line, pipe base line, ventilation pipe, sand leather cloth.

Packaging: composite cement bag, bag lining cloth, packing base lining, quilt, storage bag, mobile jacquard bag cloth.

Clothing shoes: clothing lining, floc, toe hard lining, heel lining, underwear, artificial deerskin, synthetic leather, warm shoe lining, cloth shoe sole lining.

Automotive industry: waste textile isolation hot felt, shock felt, roof, cushion lining, carpet, car door lining, car filter element, forming cushion.

Household clothing: sofa inner wrap cloth, carpet, wall cloth, mirror cloth, tea bag, vacuum cleaner filter bag, shopping bag, printed sheet, party cover, cushion, sleeping bag, dry cleaning cloth, clean cloth, curtain, tablecloth, lampshade.

Civil engineering, architecture: reinforcement, reinforcement, filtration, linoleum bottom cloth, drainage board, roofing waterproof material, railway, highway, berm, slope, port sound insulation, sewer, heat prevention, separation, drainage.

Other uses: carrier rocket, missile head heat cone, tail nozzle liner, advanced printing paper, space shuttle heat resistant tile, map cloth, calendar cloth, artificial cloth, oil painting cloth.

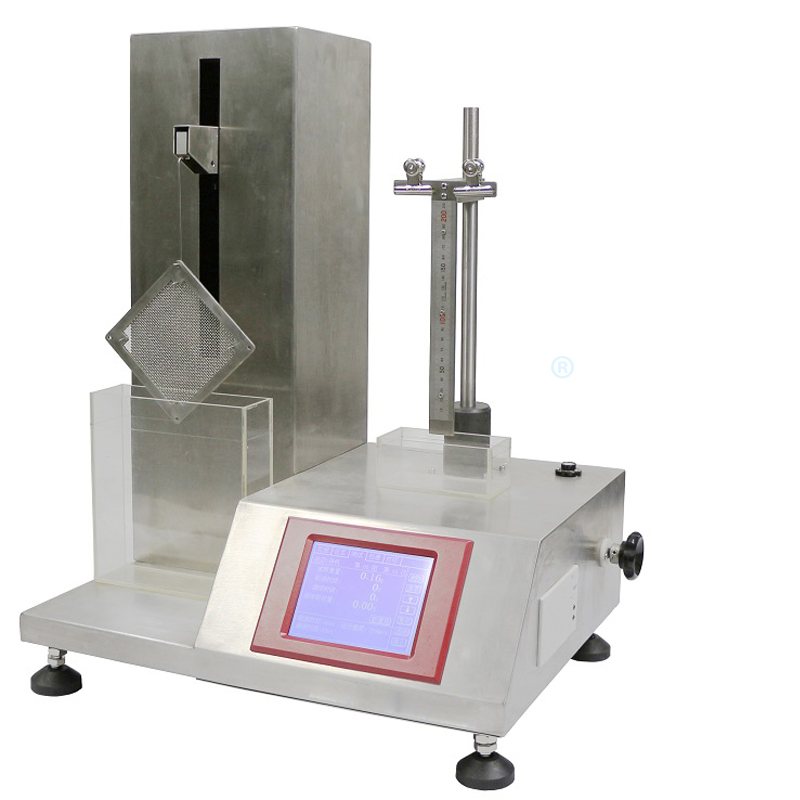

All need to be tested to determine whether the cloth is qualified. To learn more about non-woven fabric testing machines, click here.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com