+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

The measurement methods of hygroscopicity of fiber materials can be divided into direct measurement method and indirect measurement method.

1. Direct measurement method

A measurement of the weight of water obtained directly from fiber. The specific method is to weigh the actual weight of the fiber material and the weight after removing moisture to obtain the moisture regain rate of the fiber material.

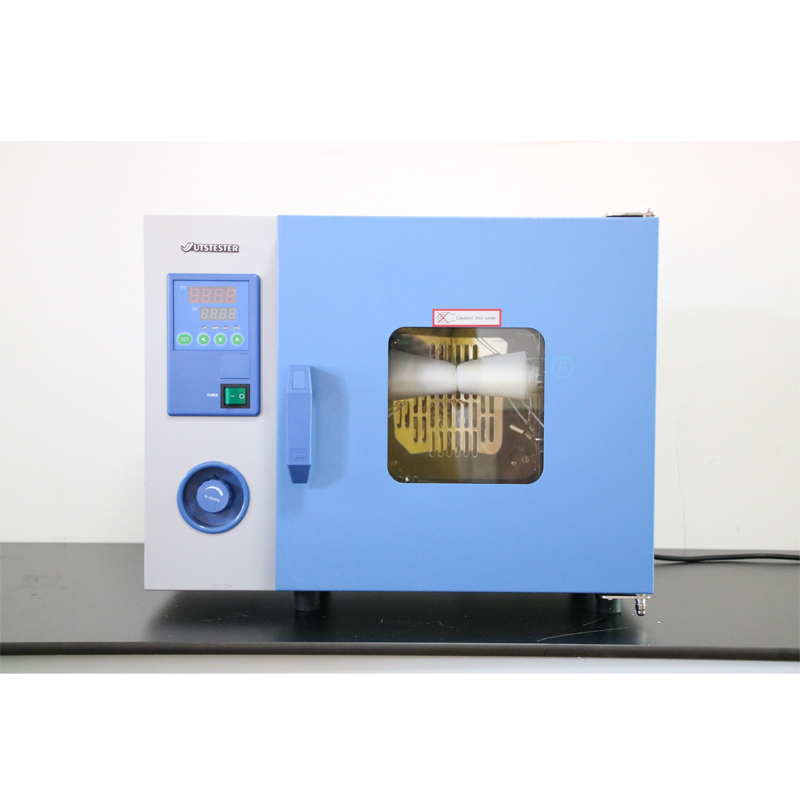

Oven drying method

Also known as oven method, is heated by electric wire and can be adjusted to a constant temperature according to need.

The temperature is determined according to the principle of rapid evaporation of water without decomposition and evaporation of fiber.

Cotton ° C (105 + 3)

Wool and most chemical fibers (105~110) °C

Silk ° C (140 ~ 145)

The drying time is limited to less than 0.05% of moisture return rate calculated by weighing twice at an interval of 15min.

Oven method for high hygroscopic fiber, there is still water residue; For hygroscopic fiber (that is, the moisture return rate is less than or equal to 0.5% fiber), the measurement results are not accurate, there is a general error of more than 10%.

The weighing methods of measured fiber in oven method mainly include heat weighing inside the oven, heat weighing outside the oven and cold weighing outside the oven.

The heat in the oven said

Use the balance hook in the red line to take the fiber in the red line.

Features: Low moisture recovery resin, easy to operate, is one of the main methods used at present.

Cases of external heat said

After drying the sample, take it out and quickly weigh it in air.

Characteristics: The measurement results are affected by the weighing time and the reliability is poor.

Outside the box cold said

After drying, the sample is placed in an aluminum or glass container and cooled in a desiccator for 30min before weighing.

Features: more accurate, more time consuming, mainly used in small sample, precision is required to use this method.

(2) infrared drying method

Also known as infrared drying. It uses infrared irradiation to remove moisture. The energy of infrared radiation is high, the penetration force is general, and the surface of the fiber can reach a very high temperature in a short time to remove the moisture. Under normal circumstances, as long as 5 to 20 minutes can be dried.

Features: infrared drying is rapid, less energy consumption than oven method, the equipment is simple, irradiation energy distribution is not uniform, often make the surface too high. If the irradiation time is over, it will make the irradiation time too long, will make the fiber coking deterioration, the measurement results are stable, the required drying time commonly used oven check.

(3) High frequency heating drying method

The use of high frequency electromagnetic waves in the memory of water molecules to produce higher energy to remove water. It can be divided into high-frequency medium heating method or capacitor heating method, the frequency range is 1~100MHz; Microwave heating method, frequency range is 800~3000MHz.

(4) Vacuum drying method

The sample was placed in a closed container and extracted into vacuum for volatilization and drying. Often with heating, improve drying efficiency.

Features: Low temperature, fast drying and uniform, can be used for high temperature resistance, low moisture recovery of synthetic fiber.

⑤ moisture absorbent drying method

Desiccant method for short, the fiber material and strong hygroscopic agent are put in a unified closed container, and the hygroscopic agent is used to absorb the air moisture in the container, so that the relative humidity in the container is approximately 0%, and the fiber can be fully dehumidified under this condition. The most effective hygroscopic agent is dried phosphorus pentoxide powder, and the most commonly used is dried calcium chloride particles.

2, indirect test method

Using the principle that the water content in the fiber material is closely related to some physical properties (such as resistance, capacitance, moisture word vibration absorption energy, etc.), the moisture content or moisture regaining rate can be inferred by measuring these properties.

Features: Rapid measurement, no fiber damage, online measurement, more interference factors, the stability and reliability of results affected.

① Resistance temperature measurement method

The different resistance values of the fiber at different water content M are used for determination. The quantitative relationship of p.M˄n=K.

(2) Capacitance temperature measurement method

The fiber material is placed in the capacitor plate, using the principle that the dielectric constant of water is greater than the fiber, and the increase of the moisture content in the material, the increase of the electric capacity, based on which to speculate the moisture content or moisture regain of the fiber material.

③ Microwave absorption method

Based on the principle that the absorption or attenuation degree of microblog is different between water and fiber, the moisture content of the fiber is expressed by measuring the attenuation amount of microblog through the fiber material.

(4) Infrared spectroscopy

The infrared spectrum has a specific water absorption wave number (2350 cm-1-- carbon dioxide; cm-1-- water), whose peak or peak area depends on the water in the fiber or the surrounding air. As long as the influence of water in the air can be photographed by blowing pure ammonia, the moisture content of the fiber can be obtained.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com