+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

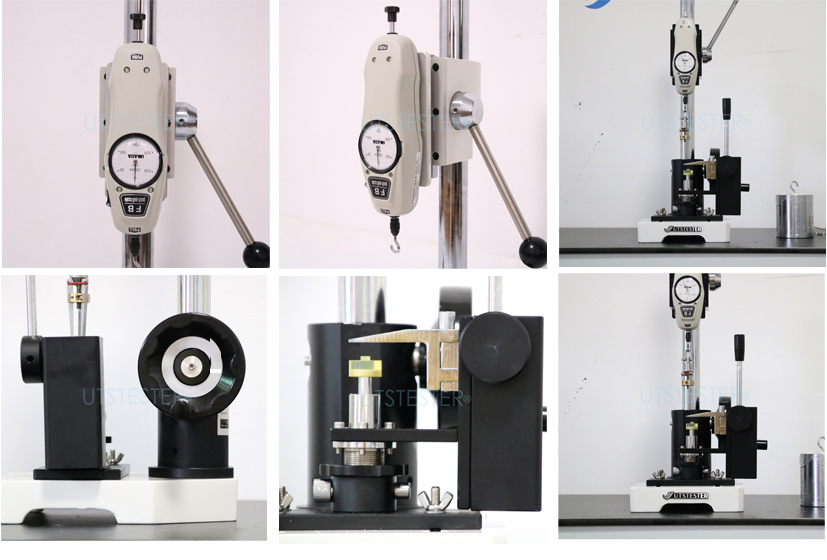

Features of manual button tension machine:

1. Integrated structure: The manual button tension machine adopts an integrated structure, which requires no assembly and is easy to use.

2. Manual control: The manual button tension machine is controlled by manual operation, which is easy to learn and does not require an external power supply.

3. Steel body: The body of the manual button tension machine is made of steel material, which is strong and durable.

4. Adjustable clamp: The clamp of the manual button tension machine is adjustable, suitable for items of different specifications and shapes.

Compared with the conventional small single-arm tensile machine, the difference:

1. Manual operation: The manual button tension machine adopts manual operation, no power supply is required, and it is easy to learn.

2. Measuring range: Manual button tensile machines are usually used for tensile testing of small items, and the measuring range is small.

3. Adjustable clamps: The clamps of the manual button tension machine are adjustable, suitable for items of different specifications and shapes.

4.Simple structure: The manual button tension machine has a relatively simple structure and is suitable for simple tension tests.

The manual button tension machine is a device for testing tension, shear, compression and bending. Here are the steps to use:

1. Place the manual button tensioning machine on a stable table to ensure that the machine is level.

2. Clamp the material to be tested in the fixture. The fixture usually provides multiple clamping methods, which should be selected according to the size and shape of the material to be tested.

3. Manually turn the handle on the gauge to initiate tension on the material in the clamp. Gradually increase the tension as needed until the test reaches the desired level or until the material being tested breaks.

4. Record the test results, including the breaking force, elasticity, hardness, etc. of the material. According to the results, the performance of the material can be evaluated and judged.

5. After the test, the jig and machine should be cleaned for the next use.

Things to note:

1. Please use the manual button tensile machine correctly according to the requirements of the machine manual, so as not to damage the machine and ensure the accuracy of the test results.

2. Keep the test site clean so as not to contaminate materials and affect test results.

3. During the test, it should be carried out in strict accordance with the test standard and test process to ensure the comparability and repeatability of the test results.

4. Operate carefully, don't get injured or damage the material and machine.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com