+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

2019-03-12

This standard USES the martindale abrasion resistance testing machine to measure the abrasion resistance of textiles. This standard is applicable to all textiles, but it may be difficult to test this method when the pile height reaches 2mm for velvet fabrics.

Principle:

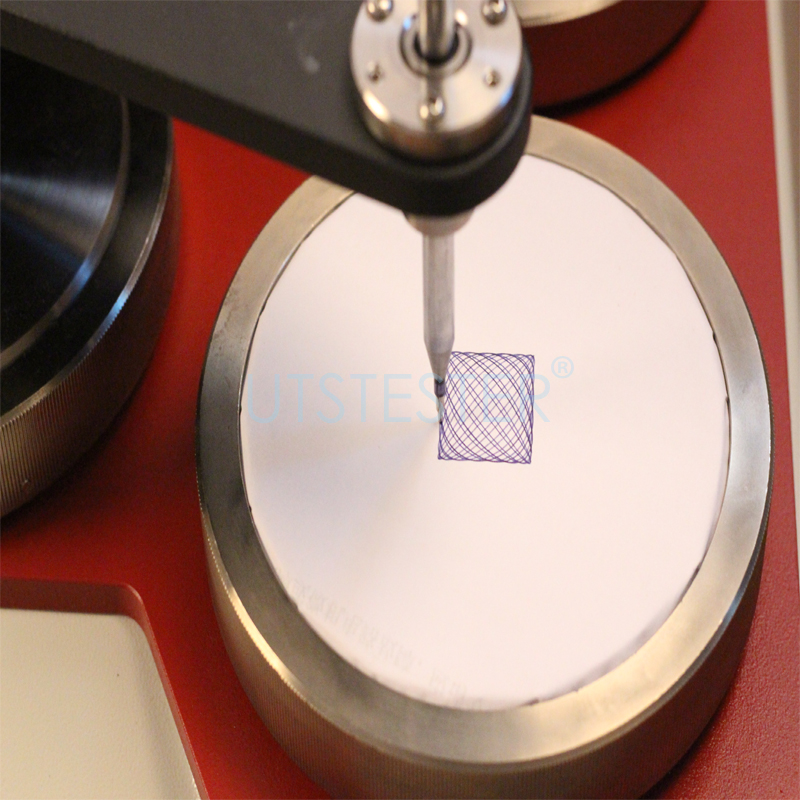

Wear-resisting test is to point to below the condition that knows pressure and abraction mode, will try to abrate by trajectory of graph of a geometry graph, graph is a straight line at the beginning, become wider and wider next form an ellipse, narrow again later, form a straight line again along former straight line opposite direction finally. The specimens are repeatedly rubbed along the above trajectories up to the specified number of turns. 11-3 describes different methods for assessing their wear resistance.

Significance and practicality:

1, in business generally think that this method is not very good, poor precision of this method in commercial contrast tests, this is due to wear tester is the nature of reason itself, using the same tester, both internally and with external comparison tests, often get different test results, while using this method is not recommended as a commercial test, but it is still widely used and that is good, especially in countries outside the United States.

In business, when there is a dispute due to different test results, buyers and sellers should conduct some comparative tests to find out the differences between the two laboratories. It may be better to choose an authority for comparison. At the same time, the samples selected by the two parties should be consistent. The general practice is that the two parties adopt the method of random sampling to find out the whole horizontal situation. Once differences are found between the two parties, they should be corrected and unified as soon as possible; otherwise, the reasons for the differences must be explained to the other party.

2. The abrasion resistance test is greatly affected by the test conditions, such as the nature of the abrasion resistance cloth, the difference in the movement of the sample on the abrasion resistance cloth, the tension of the sample, the pressure between the sample and the abrasion resistance cloth, and the size change of the sample will all affect its abrasion resistance.

3, due to the change of wear cloth in specified tests in this test result is different, wear-resisting cloth should be replaced periodically, and regularly check with standard, wear-resisting cloth is only used once, after to use period should also be replaced, the hard surface of a metal or equivalent can be used as durable wear-resistant plate, at this time in a series of tests, but don't have to change accordingly wear-resistant plate, due to the use of actual situation, the same surface of the wear plate at the same time period, changes may not be consistent. As a result of the change of surface finish, can cause the change of durable wear-resisting board, additional, as a result of the influence of other material such as test sample, need to give regularly to durable wear-resisting board clean. The manner of assessment and the different assessors will also affect the final wear test results.

4. The abrasion resistance of textiles measured by the abrasion resistance testing machine in the laboratory can be used as the wear performance index of textiles in practice and the evaluation of their durability.

5. Wear resistance assessment is routinely applied to all types of fabrics, including woven fabrics, non-woven fabrics, knitted clothing fabrics, home textiles, industrial fabrics, carpets, etc. So there are many different types of wear-resistant tester, wear-resistant cloth, testing conditions, testing procedures, evaluation of wear-resistant methods and interpretation of the results.

6. All the test methods and instruments used for the determination of wear resistance are widely used, although the results obtained by different operators and different operators may vary greatly if they are far from each other.

7. Since there is a definition for the determination of abrasion resistance, it is necessary to use a standard method to clarify the problem and minimize disputes.

Sampling:

Batch samples: the required samples can be randomly selected according to the raw materials and instructions of the buyer and the seller.

Laboratory sampling: select one garment for each test.

Test samples: sample from each laboratory by cutting 3 circular samples, up to 38mm.

Wet:

According to ASTM D1776, the sample is expected to be humidified and humidified, and the wet balance should be adjusted down in the standard environment during the test. The end point of the humidifying balance is generally considered to be when the weight change of the sample within 2 hours does not exceed 0.1%.

Before the test, the sample should be in the temperature of 21 + / - 1 ℃, relative humidity 65 + / - 2% of the standard cut wet environment at least 4 hours.

Test procedure:

1. All tests shall be carried out in a standard environment.

2, each test platform on a standard baize, is about 140 mm in diameter, and then put a piece of fairly standard wear-resisting cloth size, sample loading heavy pressure on the platform to make standard wear-resisting cloth and wool felt more flat, the baize cloth clamping and standards, then remove the sample loading weight, and check whether curly and woollen cloth clip is not tight, if need be, to sample loading.

3. For option 3, in order to assess the test results, the sample should be weighed and accurate to milligrams.

4, put positive samples in the sample rings, for sample cloth weighs less than 500 g / ㎡, put a piece of 38 mm diameter on the sample of the sponge, add metal plug-in, packed with samples according to manufacturer's instructions.

5. Put the holding sample of the packed sample on the wear-resistant platform, and add the weight of the required pressure on the holding sample, which is 9KPa for clothing fabric and 12KPa for decorative cloth.

6. According to the instruction of the instrument manufacturer, set the instrument winding number and start the operation. If it is option 1 and 2, check the samples during the test and at the end point. When the end of the test is near, reduce the number of laps between each check. If the sample is pilling, cut it with a bent shear. For option 3, after reaching the end of the run, weigh the sample to the nearest millimetre.

Evaluation:

1. Option 1: for woven fabrics, the end point of the test is two more broken yarns; for knitted fabrics, the end point is when a gap occurs.

2. Option 2: the end point of the test is when the color or appearance changes enough to make consumers complain.

3, caused by different reasons are its color changes, such as: wool or the sample surface hairiness or loop formation of fancy yarn hairiness, dyeing and blended by different types of fiber, yarn or fiber varying degrees of wear, will cause the change of the color or appearance, in this case, the end of the test commonly used color gray card.

Email: hello@utstesters.com

Web: www.utstesters.com

Tel: +86 596 7686689

Direct line: +86 15260605085

Previous article :

Tear strength test by fabric tearing testerNext article :

Application principle and method of leather softness tester