+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

2019-05-27

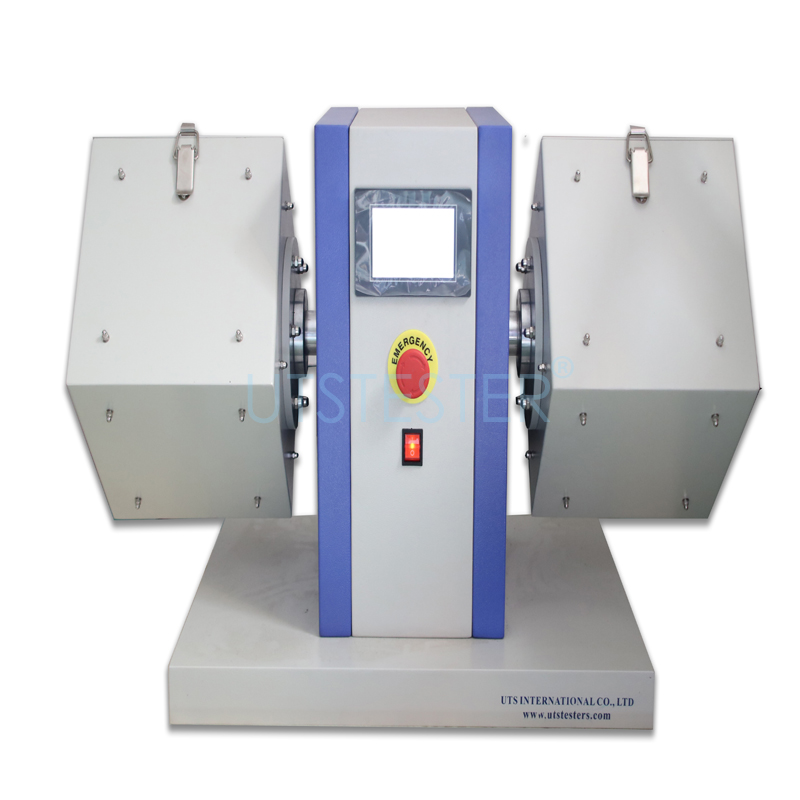

Method of rolling box pilling tester is used to detect wool knitting or pilling properties of wool-like knitted products, test standard ISO12945-1 and GB/T4802.3.

The polyurethane sample tube is the carrier of the roll box tester.A large number of tests have found that after the sample tube is used frequently for a long time, the shape of the surface of the tube basically does not change, but the elasticity of the tube body starts to decline, compared with the new tube, the hand feels stiff and the hardness is higher.According to GB/T4802.3 ─ 2008 appendix A, cork roll box line is A kind of need regular replacement of friction medium, due to the extensive use of the knitted fabric samples in the production of organic silicon, cork liner and become smooth, in the course of long-term exposure to lower friction coefficient, will reduce the pilling performance of the sample.

For this reason, how does the hardness of the polyurethane sample tube and the friction coefficient of the cork lining affect the pilling and pilling performance of the rolling box method?

I. test:

1. Sample preparation

The sample is made of pure wool knitted fabric which is easy to pilling. The pilling grade is around grade 2-4. Dark color, obvious pilling, intuitive grading, reducing subjective error.

2. Instruments and test materials

Utes rolling box-type pilling tester, speed (60 2) r/min;Laser rangefinder D3, accuracy + / - 0.3 °;Shore hardness tester, range 0 -- 100ShoreA;Sliding block;4 new polyurethane sample tubes in a group with half a year of pipe age and 4 old tubes in a group with six years of pipe age.

3. Test environment

The samples were tested in a constant temperature and humidity environment with temperature (20 2) and humidity (65 4) %.

4. Test scheme

(1) measure the friction coefficient of cork lining tan value (the following friction coefficient is expressed by tan value) : use the laser rangefinder to measure the horizontal Angle of sliding block at a constant speed, tan value is the friction coefficient of cork lining.

(2) measure the hardness of the new tube and the old tube: hold the shore hardness meter and press it on the surface of the sample tube until the lower end face of the contact is completely tangent to the tube surface, and read the HA value.The new tube and the old tube are represented by tube n and tube n# respectively (n is 1,2,3...)..

(3) the pilling performance of cork linings with different tan values was tested: samples were prepared by the same personnel, new tubes were used, the rotational speed (60 2) r/min was set, and 14400 revolutions were made. The samples were of the same sample, and the test results were graded by two persons.

(4) to test the pilling performance of new tubes and old tubes with different hardness: the same personnel shall prepare samples, use the same box with the same tan value, set the rotational speed (60 2) r/min, and 14400 revolutions, and the test results shall be graded by multiple people.

Ii. Analysis of influencing factors

1. Differences in tan values between different rolling boxes

This method can reduce the tedious work of removing and installing the cork liner, and is suitable for the inspection and daily calibration during the laboratory rolling box.Therefore, daily lab, cork line between different rolling box tan beta value differences, but the difference and meet the method standard GB/T4802 requirements.

2. Hardness difference between new and old polyurethane rubber pipes

The average hardness of the four new pipes with six months of pipe age was 52, 52, 52 and 49 degrees, and the hardness of the four old pipes with six years of pipe age was 64, 61, 60 and 57 degrees.Due to the different service life of the two groups of sample tubes, the elastic hardness value of the tube body showed obvious difference.Studies have shown that most glassy polymer materials are in a thermodynamic non-equilibrium state, which will gradually change to a stable equilibrium state under the glass transition temperature, resulting in the change of physical properties of the polymer materials.

3. Effects of different tan values of cork linings on pilling results of rolling boxes

The larger the tan of the cork liner, the more serious the pilling of the sample.The greater the difference of tan value between different box Numbers, the greater the range of pilling rating of the sample will be. For example, the difference of tan value is 0.09, which corresponds to the range of 0.5 grade of comprehensive rating.At the same time, when the difference of cork-lined tan value is small, even if the sample pilling is serious, the effect of this difference on the pilling result is not significant, or even contrary.It indicates that the sample itself has good pilling resistance. Although there is a difference in the tan value of cork lining, the difference caused by tan value does not have a significant impact on the pilling performance of the sample.

4. Influence of polyurethane rubber hose with different hardness on pilling result of rolling box

The new tube with smaller hardness has more serious pilling than the old tube with larger hardness. The average hardness difference between the new tube and the old tube is 9.25 degrees.There are obvious differences in pilling results among the same sample, the same tan value of cork liner and the same rotation speed and revolutions. With the different samples, the influence of such differences on pilling results is also different.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com

Previous article :

Common types and test methods for colour fastness of textilesNext article :

UTSTESTER provide toys safety tester