+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

2019-04-19

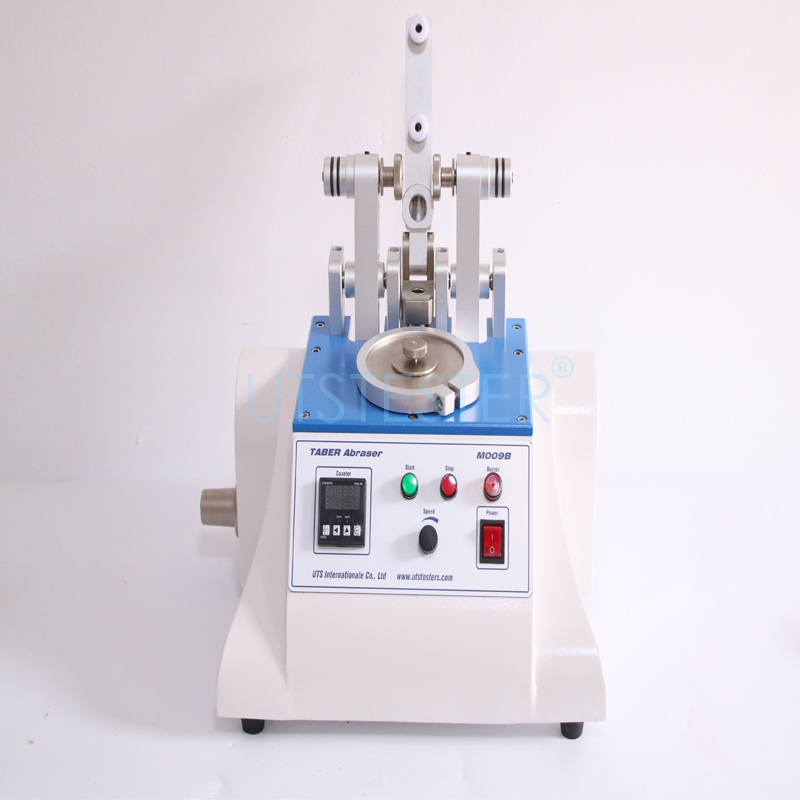

Taber wear tester(Taber Abraser tester):

Experimental principle:

The "X" type friction is produced by the rotation of a pair of friction wheels.Equipped with a full set of auxiliary weights, sample holder, friction wheel, vacuum device, membrane control keyboard and electronic counter.

Product details:

Taber abrasion tester is mainly used to test the abrasion resistance of leather and plastic materials by rotating and grinding.Select a set of weights applicable to the standard to test the material properties.Loss of weight on the outer surface of the sample, such as apparent mechanical damage.

Specification parameters:

Specimens: outer diameter 108mm, inner diameter 8mm,3mm(D)

Grinding wheel: diameter 2 "(M*45mm)1/2" (W)

Center distance of grinding wheel :63.5mm

Distance between grinding wheel and test disc center :37 ~ 38mm

Rotational speed :60/72rpm

Heavy weight: 250 g, 500 g, 1000 g

Counter :LCD,0 ~ 999.999

Volume :530 320 310+ vacuum cleaner

Weight :18kg(not including vacuum cleaner)

16. Power source :1φ、220v/50HZ

Wear index calculation formula: wear loss weight/formula number of revolutions 100

The maintenance

1. The instrument must be placed on a smooth ground before use.

2. It is not allowed to move the machine during use;

3. Select the corresponding power supply voltage, do not be too high, to avoid burning the device;

4. In case of any abnormality of the instrument, please contact our department for timely treatment;

There must be a good ventilated environment when the machine is working.

6. For each part of the key press machine, please add lubricating oil in time due to the heavy operating load;

7. Clean and keep the machine clean after each test;

8. For the control box, wipe it with a dry cloth instead of a wet cloth.

troubleshooting

1. If the power supply is turned on without display, it means that the power supply is not connected or the power indicator is damaged. If the power indicator is damaged, replace the indicator.If the power output terminal does not have power output, please check the power cord or power socket.

2. If the power is switched on and the power indicator has instructions, press the start button and the machine does not work. Please check whether the relay is disconnected or not.

3. When the test to the counter set number of times, the motor still does not stop working, (1), the counter is damaged;2) after the counter is set for several times, the reset button is not pressed to write.

4. If the power indicator light is on and the counter is not displayed, it means that the counter is damaged, the counter shall be replaced.

Calibration method

1. Scope of application of calibration method

This calibration method is applicable to the taber wear tester.

2. Technical requirements

(1) table speed: 60r/min 2r/min;

(2) additional weight: 2509 lg;5009-29;7509-29;10009-29.

3. Reference standard for calibration

(1) stopwatch, accuracy 0.1 s.

(2) electronic scale range 30009, accuracy 19.

4. Calibration steps

(1) in the first step, set the rated revolution of the counter to 60r/min;Step 2: press the RST key to reset the counter;Step 3, press the start button and start the stopwatch.The fourth step, the counter records to 60 turns, the test machine automatically stop, stop stopwatch timing;Fifth, record the stopwatch time;Repeat the above steps from step 2 to step 5, and both times should be within the range of 60s 2s.

(2) the mass of 2509, 5009, 7509 and 10009 weights were weighed by an electronic scale, and the weight of 2509 should be 2509+lg.The weight of 5009 should be 5009 29;The weight of 7509 should be 7509+29;The weight of 10009 should be 10009 29;If it does not meet the requirements, the weight should be increased or decreased, and then be weighed again until the requirements are met.

5. Calibration test records and result processing

(1) check record of the Taber wear tester

(2) the calibration cycle is one year.

Email: hello@utstesters.com

Web: www.utstesters.com

Tel: +86 596 7686689

Direct line: +86 15260605085

Previous article :

UTSTESTER Holiday NoticeNext article :

Note for ASTM E84 tunneling surface combustion test