+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

2019-04-25

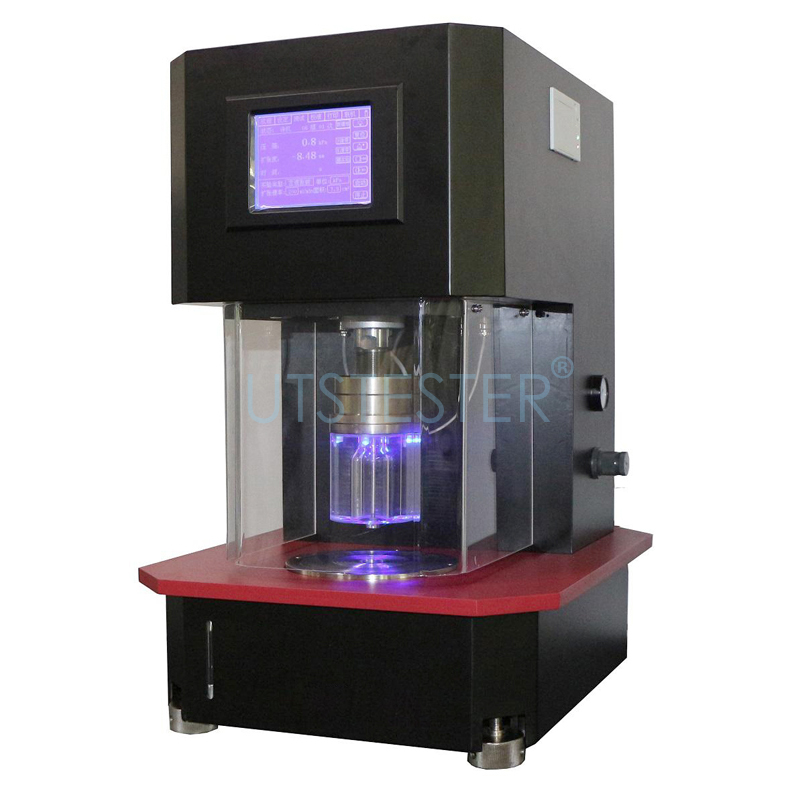

Pneumatic bursting tester for woven fabric, fabric, not deformation, the direction of the weft yarn fabric by two groups of weft yarn shear against each other, its elongation deformation is bigger warp/weft direction, under the effect of pressure, the first in the deformation and strength the weakest point in the direction of the smaller yarn faults, and then along the warp or weft to relative to tear, and tear into a straight line.If the warp and weft deformation capacity of the fabric is similar, the warp and weft yarn will break at the same time when the fabric is broken, and the crevice is usually L or T shape, it indicates that the warp and weft yarn plays the maximum role at the same time, and the bursting strength is higher than the linear crevice.

For knitted fabrics, when the fabric is burst, all the coils join together to endure elongation deformation until the fabric is torn.

For nonwoven fabric, the main is the fracture of the fiber and the loosening of the fiber mesh, the top break is a bulge of loose fiber package, the bursting is the fiber mesh pulling loose and cracking.

When using the pneumatic fabric dilatometer to test, the sample is clamped on the expandable diaphragm, and the pressure is applied under the diaphragm in the way of gas pressure to make the diaphragm and sample expand, and the pressure is increased at a constant speed until the sample is cracked, and the bursting strength or expansion degree of bursting is measured.

Email: hello@utstesters.com

Web: www.utstesters.com

Tel: +86 596 7686689

Direct line: +86 15260605085

Previous article :

How to carry out self - inspection and maintenance of washing machine?Next article :

Application of single yarn strength machine