+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

2019-07-01

Electronic yarn twist tester instrument is used for determining the twist of various yarns.

The properties of the instrument are in conformity with the new national standard GB2543.1~GB2543.2 Textiles--Determination of twist in yarn, the international standard ISO2061 Textiles - Determination of twist in yarn - Direct counting method, the standard of the former Ministry of Textile Industry FJ547 Test method for open-end gray cotton yarn, and the national industrial standard FZ/T10001 Determination of twist in open-end yarn – untwist-retwist method.

Main Technical Specifications

1.Measurement range: for all kinds of yarns.

2.Yarn tension: adjustable by a set of weights depending on the type of yarn.

3.Rotating speed of gripper: 1500 r/min, 800 r/min, slow inching speed.

4.Length of measurement: 25, 50, 100, 200, 250, 500 mm.

5.Number of measurements: no more than 99 cycles.

6.Measurement method: a. Direct counting method;

b. Untwist-retwist method;

c. Double untwist-retwist method;

d. Three-time untwist-retwist method.

7.Method of measurement data output:

a. Display output

b. Print output: Xi for twist value of each test; for average twist value of each batch of tests; Nn for number of tests; N1for number of tests below the average twist; S for mean square deviation; H for coefficient of mean deviation; CV for coefficient of variation; and α for twist factor.

8.Power source: 220V±10%, 50Hz.

9.Power requirement: low than 25W (main unit).

10.Operational environment requirement: temperature 20oC±10oC.

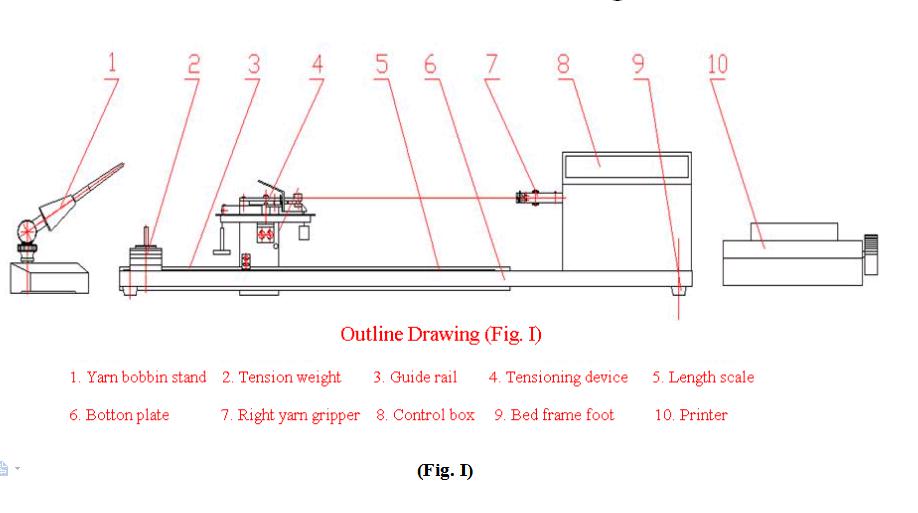

Main Structure

Electronic yarn twist tester mainly consists of a control box, a tensioning mechanism, a yarn bobbin stand, a data processing system and other components.

1.The control box is provided with a right yarn gripper that is directly driven by a micro-motor, and all functional switches.

2.The tensioning mechanism is loaded with tension in a horizontal mechanical way and the tension can be varied indefinitely with weights in accordance with the requirements of the test method.

3.The yarn bobbin stand can be installed and adjusted freely by the user to meet test requirements.

4.The data processing system is mainly composed of a built-in computer, a display and a printer.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com

Previous article :

Three different test methods for fabric tear strength testerNext article :

knowledge of the Bite Test Clamp