+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

In daily life, down penetration can occasionally occur in down jackets and duvets, creating a negative consumer experience.

1. Down Burst Factors

Down feathers in down products contain a large amount of stagnant air. When a down quilt is squeezed, the air inside the down product is expelled through the fabric and needle holes. These airborne particles, called down filaments (hereinafter referred to as flying filaments), are carried by the high-speed airflow and attached to the fabric of the quilt, causing down bursts.

Down bursts can occur for a variety of reasons, such as insufficient fabric density, large needle holes, or poor down quality. This directly impacts the appearance and warmth of the down.

1.1 Down Structure

Because down is composed of protein molecules with a unique tree-like structure, they are easily charged by friction, causing like charges to repel each other and leak through micropores or seams. When down is subjected to external forces, it tends to rebound. During this rebound, air bursts through the fabric, pushing down feathers out from both sides. Furthermore, down is composed of a large number of components, and the tips of down filaments, feathers, and feathers are sharp, making it easy for them to burst through the fabric.

1.2 High Unfinished Down Content

The higher the unfinished down content in a down, the more it will be pierced; conversely, the lower the unfinished down content, the less it will be pierced.

For example, in 90% down that meets the national standard GB/T 14272-2021 "Down Clothing," the detectable unfinished down content can reach up to 10%. With such a high unfinished down content, it's difficult to minimize or eliminate piercing.

Experimental data shows that as the total amount of unfinished down decreases, the number of pinhole-pierced down decreases. When the unfinished down content drops below 3%, the number of pinhole-pierced down decreases by over 80% compared to down with a 12% unfinished down content.

1.3 Low density of the outer and inner lining material, resulting in high air permeability

In existing down jacket construction, the outer fabric, lining, or lining material may all be used to encase the down, and come into close contact and friction with the down.

The lower the density of the outer and inner lining material, the larger the gaps between the fabric fibers, resulting in higher air permeability and an increased chance of flyaway fibers penetrating the fabric. Some companies use calendering or coating processes to reduce fabric air permeability, achieving better initial down-proofing properties. However, as the down jacket is washed and rubbed, the down-proofing effectiveness of calendering or coating diminishes, and down penetration increases. Only by increasing the fabric density to achieve an air permeability of 1-3 mm/s can long-lasting down-proofing properties be achieved.

1.4 Filling Sequence

Currently, most factories use down filling machines. There are two filling processes: filling first and then quilting the down bag; quilting the down bag first and then filling each cell with down. The first filling process is more efficient, as each quilting needle hole compresses some down. These down fibers are close to the needle holes and easily escape through them due to airflow or friction. The second filling process is less efficient, but the quilting needle holes don't compress the down. To escape, the fibers must penetrate the down surrounding them and escape with the airflow, making this process significantly more challenging than the first. Experimental data shows that the amount of down that escapes when quilting first and then filling is reduced by over 60% compared to filling first and then quilting.

Taking all of the above factors into consideration, if companies want to ensure low down penetration in down products, they must implement effective measures and increase product costs to address this issue.

2. Anti-Down Penetration Test Method (Rotating Box Method)

2.1 Ready-to-Draw Down Garments

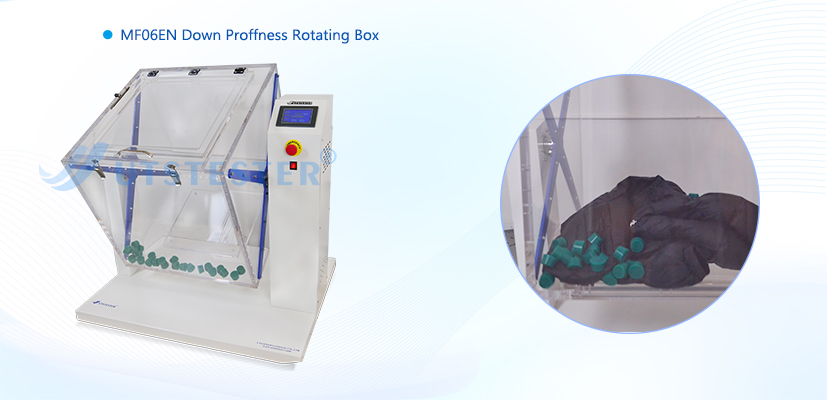

Principle: The entire test sample is placed in a rotating box of a testing instrument containing shaped silicone rubber balls. The rotating box rotates at a constant speed, bringing the shaped silicone rubber balls to a certain height and impacting the sample within the box, simulating the various squeezing, rubbing, and collision experiences experienced by the test sample during wear. The overall anti-down penetration performance of the garment is evaluated by calculating the number of down, feathers, and down fibers that emerge from the sample per unit area.

2.2 Down Quilts

Principle: Sample bags of fixed size are cut from the down filling area/layer of a finished down quilt or composite down quilt and placed in a rotating box of the testing instrument filled with hard silicone balls. The rotating box rotates at a constant speed, carrying the silicone balls to a certain height, where they impact the sample inside the box, simulating the various squeezing, rubbing, and collision effects that down quilts experience during use. The overall down penetration resistance of the down quilt is evaluated by counting the number of feathers, down, and down fibers that emerge from the sample bag.

[GB/T 12705.2-2009 "Textiles - Test Method for Down Penetration Resistance of Fabrics - Part 2: Rotating Box Method"]

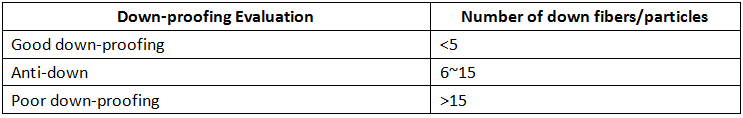

Evaluation of anti-down drilling performance:

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com