+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

1.Thickness measurement and textiles

The thickness of compressible textiles is usually measured in accordance with EN ISO5084. The standard recommended pin diameter is 50. 2 mm. The pressure applied on the textile is 1. 0 kPa, for some special textiles, such as machine textiles with rough surface, plush machine textiles and some warp knitting textiles, the pressure can only be 0. 1 kPa. The fact that textiles are compressible has been clearly stated in DIN 53885 standard. In the standard, the compressibility of textiles can be used at 0. 2 and 2. Different thickness measured at 0 kPa pressure is characterized.

It has been known from the literature that the relationship between the pressure applied on the textile and its thickness is easily obtained on the spacer textile. There are also reports on the theoretical and experimental studies on the true diameter of yarn and the shape of fiber aggregates under certain pressure.

In the literature of Eggert et al., the exponent is called "flexability", which is a variable, and the values here are 3 and 1/3 respectively. However, this was questioned, and was accused of representing only the test results. In order to compare this value with the results obtained in this study, the same fitting function is selected, and the fitting process starts from the origin. In addition, in practical application, needle textiles of different thicknesses are evaluated according to the ENISO 5084 standard in large page order of their compressibility.

2. Correlation between pressure and measured textile thickness

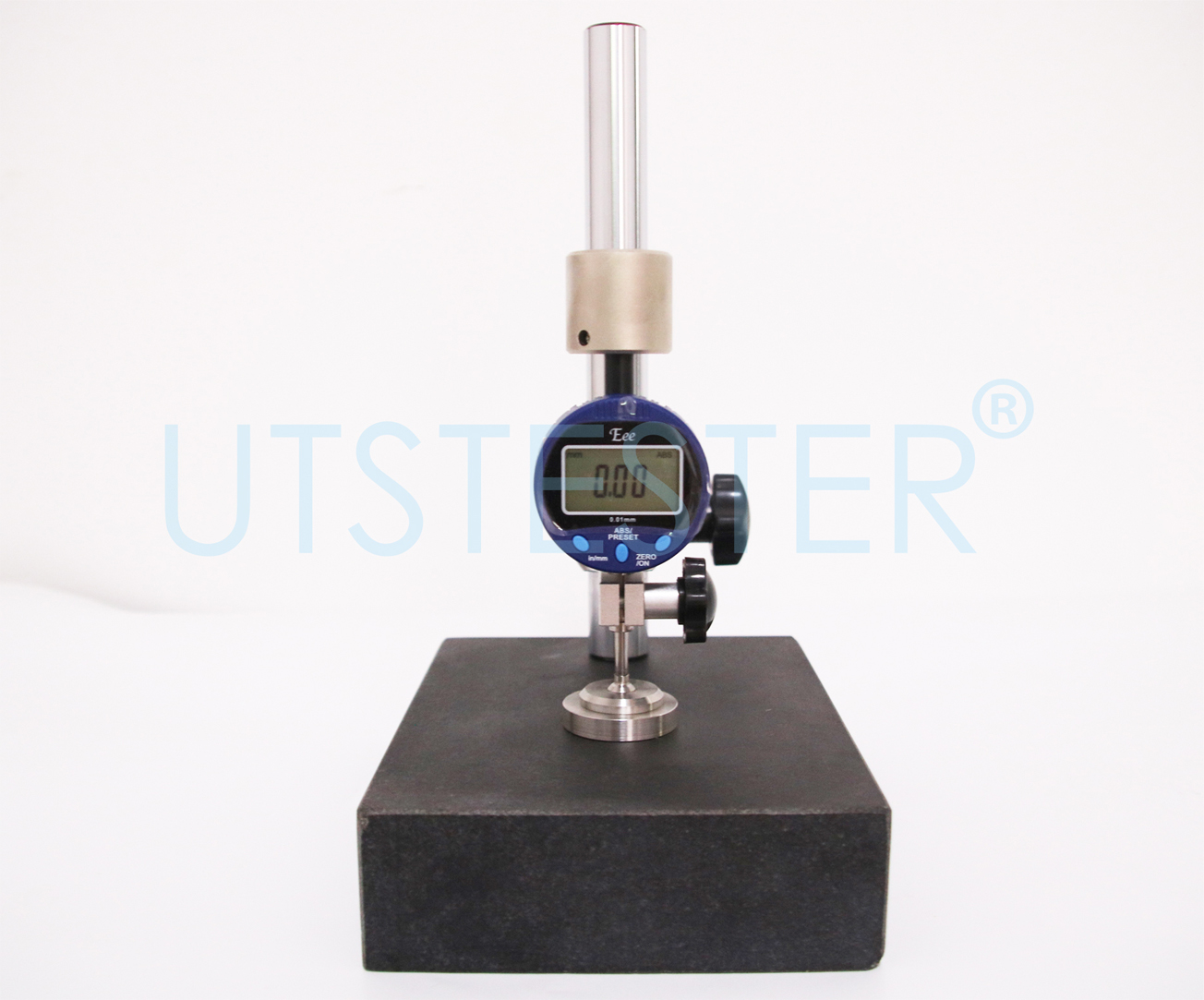

In the standard EN ISO 5084 and DIN 53885, the thickness of the textile is only determined by one or two different pressures. In the recent research project, multiple pressure values are adopted to test the thickness of the needle textile with the Frank thickness meter. FIG. L shows the test results of a polyester weft knitting needle textile (4 knitting in front of the needle bed and 1 knitting in front and back of the bed). Obviously, the} is set according to formula (2) to fit parameters, which can be well fitted. According to van Wyk's equation, the index obtained is not 3, but close to 9. According to these values, the thickness of the textile in the relaxed state can be approximately estimated as 1. 68 mm, at the minimum pressure of o. At 1 kPa, the deviation between the measured value and the true value is about 5%. Therefore, even using the minimum pressure standard recommended by EN ISO 5048, there will be a significant deviation between the measured value and the real value.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com