+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

1. Cause of pilling

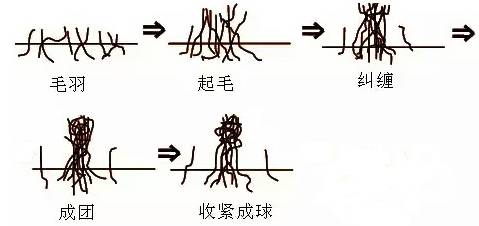

Clothes in the washing process or the actual wearing process, constantly from with the outside world, its friction, make the surface of the fabric show in fabric fiber end, on the surface rendering many unpleasant hairy for "fluff", namely if the fluffy cannot fall off in time, in the process of continue to wear will be intertwined with each other, be rub into spherical particles, the particles called "ball".

Relevant studies show that:

(1) Cotton, hemp, silk and other natural fibers (except wool fabrics) have a small degree of pilling.

(2) Common chemical fibers such as polyamide fiber, polyester fiber, acrylic fiber, polypropylene fiber and regenerated cellulose fiber are easy to be extracted and formed into pilling.

(3) The pilling degree of chemical fiber and natural fiber will increase after blending.

2. Detection and evaluation

A Circle Trajectory method (GB/T 4802.1-2008)

It is commonly seen in FZ/T 73020-2012 Knitted Casual Wear, GB/T22849-2014 Knitted T-shirt, FZ/T 81004-2012 Dress and Skirt Cover, FZ/T 81007-2012 Single and Clip Clothes, AND GB/T 2664-2009 Suit and Coat in the standard of clothing products. Circle trajectory method is used to test the pilling performance of fabrics.

Test principle: the sample is brushed through a standard friction head, then pilled with standard wool gabardine.Then the pilling performance was evaluated by visual description under the specified light conditions.

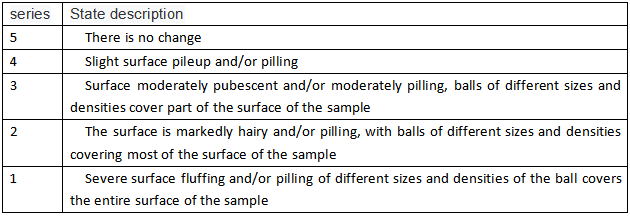

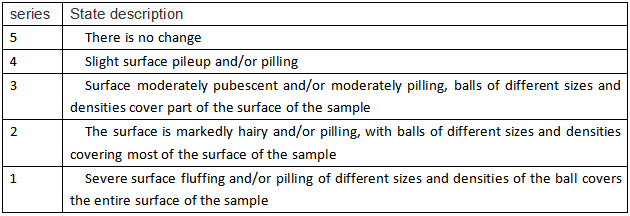

Results the evaluation

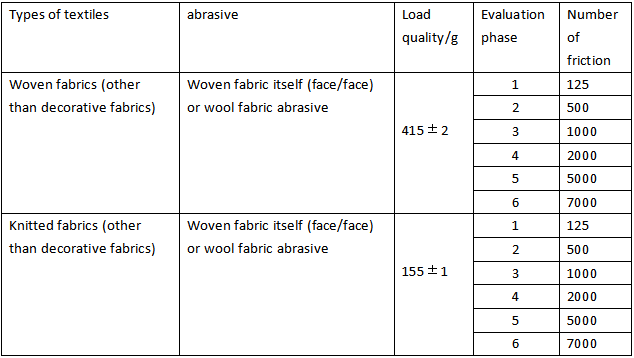

B Martindale Method (GB/T 4802.2-2008)

Commonly seen in the bedding product standard GB/T 22843-2009 "Pillow and mat Products", GB/T 22796-2009 "Quilt and quilt Cover", FZ/T 62027-2015 "Woollen Fabric sheet", etc. Martindale method is used to test the pilling performance of fabrics.

Test principle: According to the test parameters, under the specified pressure, the circular sample will rub against the fabric itself or the standard wool abrasive with the track of The Lissajous graph. The sample will be able to rotate freely around the central axis perpendicular to the sample plane.

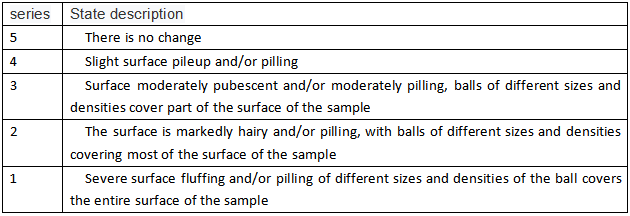

Results the evaluation

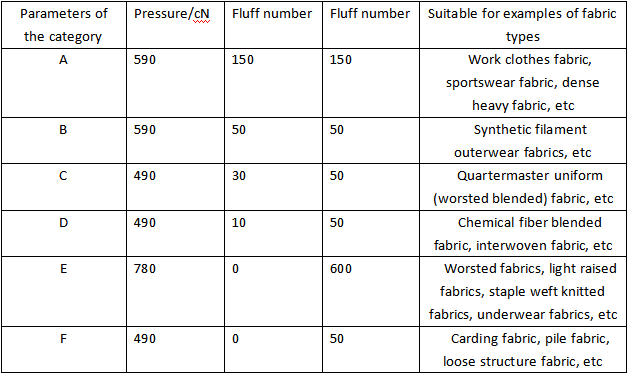

C Pilling box method (GB/T 4802.3-2008)

It is commonly seen in FZ/T 73005-2012 Low-Wool Blended and Wool-like Knitwear, FZ/T 73018-2012 Wool Knitwear, FZ/T 73009-2009 Cashmere Knitwear, AND FZ/T 73010-2008 Knitwear. Pilling box method is used to test the pilling performance of fabrics.

Test principle: the sample mounted on the polyurethane tube is turned arbitrarily in a wooden case lined with cork at constant speed.After a specified number of flips, the pilling and/or pilling performance was evaluated visually.Generally, woolen fabrics are flipped at 7,200 RPM, and worsted fabrics at 14,400 RPM.

Results the evaluation

D Random roll method (GB/T 4802.4-2009)

This method is rarely cited by domestic products and frequently used by foreign products.

Test principle: along the warp/weft to 45 ° cutting square sample after using adhesive seal edge into a random roll of cork gasket type pilling box, short and filled with a small amount of gray cotton in the cylinder test of storehouse, the impeller and the effect of air pressure free rolling friction, the friction involved in the process of the sample and samples as well as the friction between samples and liner friction.After 30 minutes, the pilling performance was evaluated by visual description under the condition of specified light source.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com