+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

Tensile Strength

Test method:

ASTM D 5034, determination of breaking strength and elongation of fabric.

Key points:

This test provides information on the potential breaking strength of the garment fabric when used by consumers.

Limitations:

It is not recommended to test knitted fabrics and other knitted fabrics with high elasticity (greater than 11%).

Test conditions:

The cloth should be placed in a constant temperature and humidity environment (21 ± 1℃ temperature and 65 ± 2%RH relative humidity) for at least 4 hours before testing.

Sample size:

4" x 8"(at least 4" x6"), both meridional and zonal.

Result:

The force recorded when the fabric cracks or breaks is the breaking force.

Tearing Strength

Test method:

ASTM D 1424, determines that flat woven fabric has a crack and continues to tear with the force required by the swing tester.

Key points:

This test provides information on the potential tearing strength of the garment fabric when used by the consumer.

Application:

Treated or untreated plain woven fabric, including heavy pulp, heavy glue or resin.

Not suitable for:

knitted fabrics, Felt and non-woven fabrics.

Test conditions:

The cloth is placed in a constant temperature and humidity environment (21 ± 1℃ temperature and 65 ± 2%RH relative humidity), at least 4 hours before the test.

Sample:

Both warp and weft must be tested.

Bursting Strength

Test method:

ASTM D3786 -- Use of a hydraulic rubber film bursting strength tester to determine the bursting strength of textile fabrics.

Key point:

Measuring the potential blasting force of knitted fabric.

Test conditions:

The cloth should be placed in a constant temperature and humidity environment (211° C temperature and 65 ±2% relative humidity) for at least 4 hours before testing.

Procedure:

The sample is placed on an extendable rubber film and locked. The rubber film is hydraulically extended and cracks the sample.

Scope of application:

knitted fabrics and non-woven fabrics.

Limitations:

It is not recommended to test flat weaves not covered with gum.

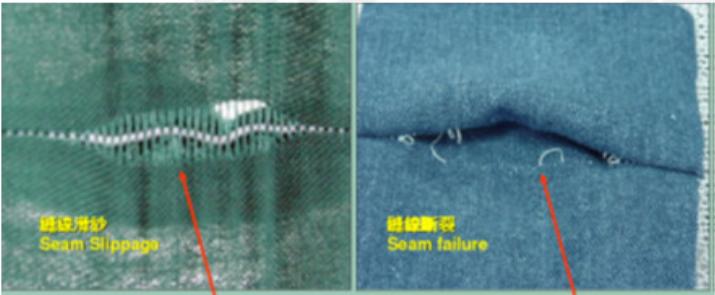

Seam Slippage

Test method:

Determine the force required to slide the weft in the direction of the warp or warp in the direction of the weft in a plain woven suture according to ASTM D 434.

Important:

Determine the tendency of yarn to slip from the stitches.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com