+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

There are many kinds of knitted fabrics. In the actual use and washing process of these knitted fabrics, the continuous friction causes the fibers on the surface of the fabric to show up on the surface of the fabric, and the wool appears on the surface of the fabric. This phenomenon is called "fluffing".If they do not fall off in time, they become entangled with each other and are kneaded into many small spherical particles, often called "pilling".These protruding hairballs on the surface of the fabric will easily make dirt and dust stick to it, which will seriously affect the wearing performance and appearance of the fabric.

Polyester/cotton, polyester/viscose blended fabrics are durable, beautiful and comfortable to wear. However, due to constant friction in the washing process, the polyester/cotton blended knitted fabrics are more serious than natural fibers in pilling phenomenon.It is very important to evaluate the fuzz and pilling property of t/c knitted fabric objectively and accurately.

A method for testing the pilling and fuzzing properties of fabrics

There are four main testing methods for fabric pilling and pilling: roughing pilling test method, martindale wear test method, rolling box pilling method and circular track pilling method.

Martindale method

Under the specified pressure, the circular sample on the sample fixture is rubbed against the abrasive material on the grinding table (the same fabric or wool fabric abrasive material as measured) according to the lisharu curve.The specimen can freely rotate about a central axis perpendicular to the specimen plane.After the specified friction stage, the fuzz and pilling grades of the samples were evaluated by visual description.

Pilling box method

A sample mounted on a polyurethane tube is flipped inside a wooden box lined with cork at a constant speed.After the specified number of flips, the pilling performance was evaluated by visual description.

Random roll method

Put the sample into the test box. Under the rotating action of the impeller, the cork lining of the storage box is continuously and randomly rubbed. After reaching the set time, the sample is taken out for rating.

Circular locus method

According to the prescribed methods and test parameters, nylon brush and fabric abrasive or only fabric abrasive are used to make the samples bristle and pilling.Then, the visual description and evaluation of pilling and fuzz performance were carried out under specified lighting conditions.

This paper mainly introduces the rolling box method of fuzzing and pilling test, based on the standard of GB/T4802.3.

[scope of application] :

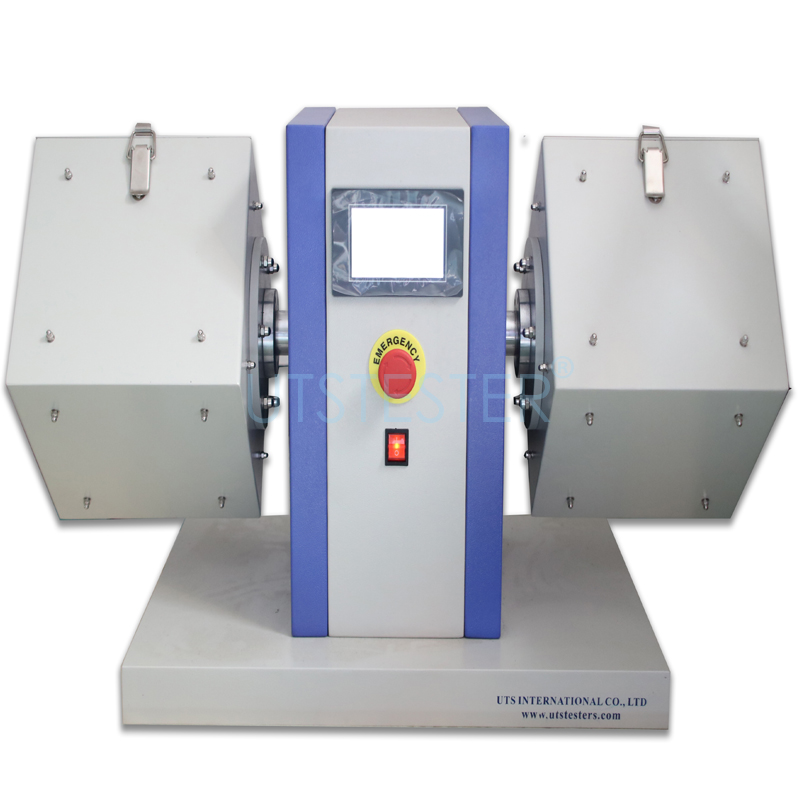

Pilling testing equipment is designed and manufactured according to the requirements of national standard GB/t4802.3-2008 "textile -- fabric pilling test -- pilling box law", which is used for pilling test of wool, knitted fabrics and other easily pilling fabrics to evaluate the pilling grade of fabrics under no pressure.

[technical parameters] :

1. Number of pilling boxes: 2, 4, 6, 9

2. Internal space size of the box: 235mm×235mm×235mm (including cork lining)

3. Box rolling speed: 40--80r/min(adjustable)

4. Rolling times of the box: 2 ~ 999999 (optional)

5, be: appearance Φ 31.5 x 140 mm, weight is 52.25 g

6. Sample: 125mm×125mm

7. Motor: reduction motor 60W

8. Power supply: Ac 220V± 10% 50Hz

[test process] :

1. Sample making

(1) pretreatment: if pretreatment is required, samples can be washed or dry-cleaned by the method agreed by both parties.(pretreatment is recommended to protect the friction surfaces and sample tubes of the pilling box from residual lubricants or finishing agents on the fabric)

(2) cut 4 samples from the fabric samples with the size of 125mm*125mm, and cut another cloth sample with the same size as the comparison sample required for grading.The 2 samples were folded vertically facing inward, and the 2 samples were folded horizontally facing inward. The sewing machine was used to sew the 2 samples at a distance of 12mm.

(3) turn the suture sample outward with the front facing outward.Cut 6mm ends at each end of the sample tube to remove sewing deformation.Place the sample on the polyurethane sample carrying tube and fix it with PVC tape (ensure that 6mm of both ends of the polyurethane are exposed, and the tape length should not exceed 1.5 times of the circumference of the polyurethane tube).

(4) wet

2. Test procedures

(1) clean the pilling box

(2) put 4 sets of good sample tubes into the box, close the box cover firmly, and dial the counter to the required rotation times.

(3) preset rotation number.Number of agreements.In the absence of agreement, 7,200 rotations were turned over for the woolen fabric and 14,400 rotations for the fine imitation fabric.

(4) start the pilling box. After the test, take out the sample, sew out the thread, and conduct sample rating.

[test results] :

Pilling grade evaluation: under the standard light source, the pilling grade is compared with the standard sample. In other words, multiple raters are allowed to compare and analyze the sample with the standard sample in the rating box, and the result is taken as the pilling grade of the sample.The sampling method USES five grades, which are 1-5 respectively. The smaller the level is, the more serious the fuzz and pilling is; on the contrary, the better the anti-fuzz and pilling performance it is.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com