+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

The classification of leather is quite complex. According to the tanning method, it can include chrome tanned leather, vegetable tanned leather, oil tanned leather, aldehyde tanned leather and combined tanned leather. According to the layer, there are first-layer leather and second-layer leather. The first-layer leather includes full-grain leather and trimmed leather; the second-layer leather includes pig second-layer leather and cow second-layer leather. In addition to the above classification methods, since there are many types of leather materials, we are generally more accustomed to classifying them according to their types. It is mainly divided into two types: natural leather and substitute leather. Natural leather is what we call "genuine leather" and is mostly composed of cowhide, sheepskin, pigskin, miscellaneous leather, shaved leather, etc. Among them, cowhide, sheepskin and pigskin are the three major leather types used as raw materials for tanning. Substitute leather is what we call "fake leather" and is a general term for artificial materials such as PVC and PU. Because synthetic leather or other leather-like products are actually artificially synthesized products from basic chemical raw materials.

Methods for judging and testing the wear resistance of leather:

The wear resistance of leather is the property of leather to resist wear and tear. Leather wear and tear is an important cause of leather damage. Although the abrasion fastness of leather has not yet been assessed as a national standard, the abrasion resistance test of leather is still indispensable for measuring its quality, and it is of extremely important significance for evaluating the wearing fastness of leather.

Judgment method:

There are two methods to judge the wear-resistant performance index of leather, namely the end point method and the appearance change method.

1.1 End point method: The number of rotations required to remove 1 mm of leather is the thickness index of wear resistance, and the number of friction rotations is recorded as the wear resistance index.

1.2 Appearance change method: After the test sample has been rubbed for a certain number of times, observe its appearance changes, such as color change, degree of wear and other appearance changes, as the wear resistance index.

Test Methods

1. Flat grinding method

Reference standard: "GB/T 21196-2007 Determination of abrasion resistance of fabrics by Martindale method".

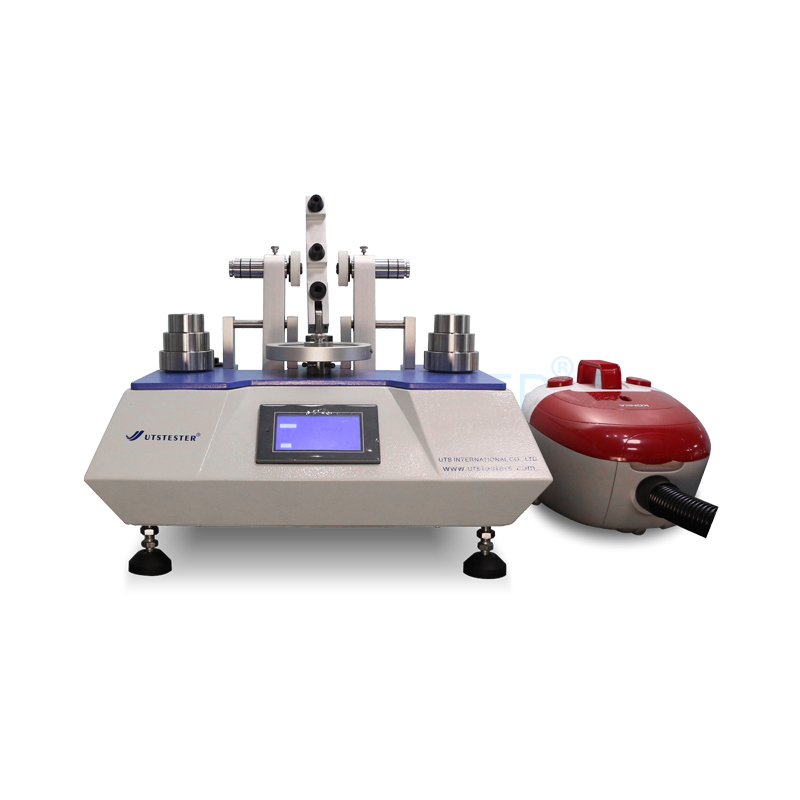

Testing instruments: There are many types of fabric flat grinding testers. Currently, the most commonly used in the testing industry is the Martin denier tester. Therefore, the flat grinding method is often called the MARTINDALE friction testing machine method.

Test principle: A circular sample installed in the sample fixture of the Martindale abrasion tester is rubbed with the abrasive (i.e. standard fabric) in the plane motion of the Lissajous figure under a specified load. The sample clamp can rotate freely around its axis perpendicular to the horizontal plane. The wear resistance of the leather is determined based on the total number of frictions when the sample is damaged.

Test method: During the test, a test sample of a certain size is brought into contact with a standard abrasive under a specified pressure, and the sample is moved relative to the abrasive along a Lissajous trajectory, so that the test sample is uniformly worn in multiple directions.

2. Taber wear-resistant method

Reference standard: "GB/T 2726-2005 Determination of wear resistance of leather in physical and mechanical tests".

Testing instrument: TABER wear resistance testing machine

Test principle: Pre-grind for 25 revolutions. Place the tested sample on the horizontal platform of the TABER wear-resistant testing machine and rotate it. Two grinding wheels are given a specific pressure to press on the test piece. The axis of the grinding wheel is parallel to the horizontal plane. With the grinding wheel facing outward and the other facing inward, record all changes of the test piece within a certain period of time.

Test method: Use a cutter to cut a sample with an outer diameter of 108mm and an inner diameter of 8mm. Then put a hard sticker of the same size on the back of the sample. Place the center hole of the sample on the rubber pad of the screw, put the gasket on, and fix the sample with a compression nut. Then put the fixing ring on and tighten the fixing ring screw with a wrench. Install two H18 grinding wheels on the support arm. Each grinding wheel exerts a force of 250±10g on the test sample, ensuring that the side with the label faces outward, so that the load of the grinding wheel is 500g. Connect a vacuum cleaner and remove the dust from the vacuum cleaner. Connect the hose to the connector on the left side of the machine and start the vacuum cleaner. Set the number of tests according to the standard and set the rotation speed to 72 rpm. Then activate the start button, start the instrument with a rotation speed of 60±5 times/min, rotate it horizontally, and perform the test according to the required number of times. During the test, use a brush to remove the attachments on the surface of the sample, observe the wear and tear of the test, grind the leather to the designated end point, and record the final number of revolutions. It is of little significance to compare the test results obtained by testing different materials using the same experimental method, but the conclusions drawn from these results are consistent. Therefore, any method can independently quantitatively evaluate the wear resistance of materials. In general, natural leather materials are softer and therefore have poor wear resistance. Coated leather has a hard texture and is not easy to wear, so it has better wear resistance.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com