+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

I believe everyone has heard the saying "fire and water have no mercy". In life, we must do a good job in waterproofing and fire prevention to avoid causing harm. To a certain extent, the flame retardancy test is a fire test.

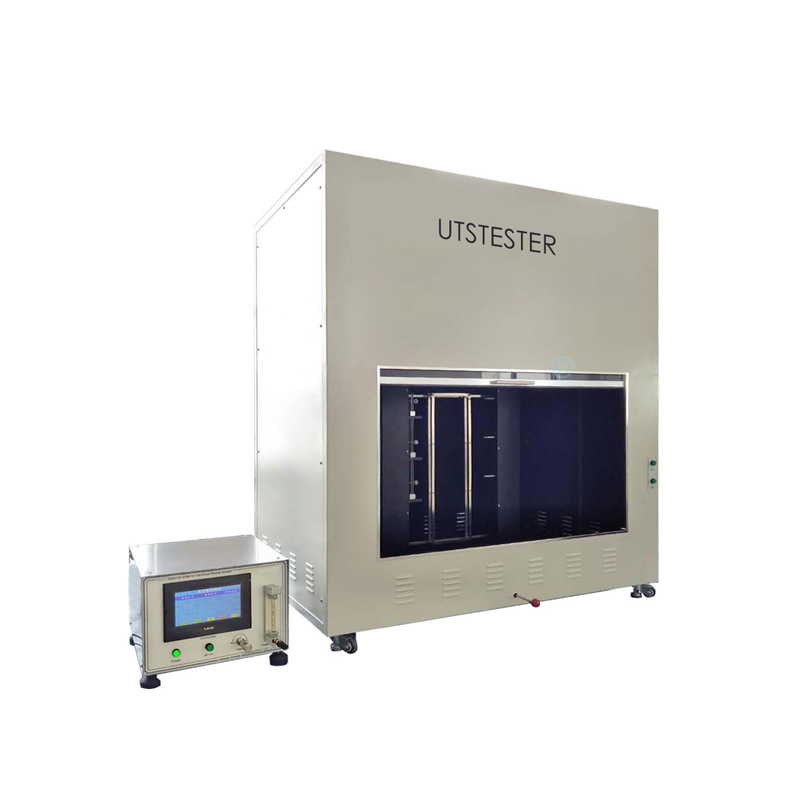

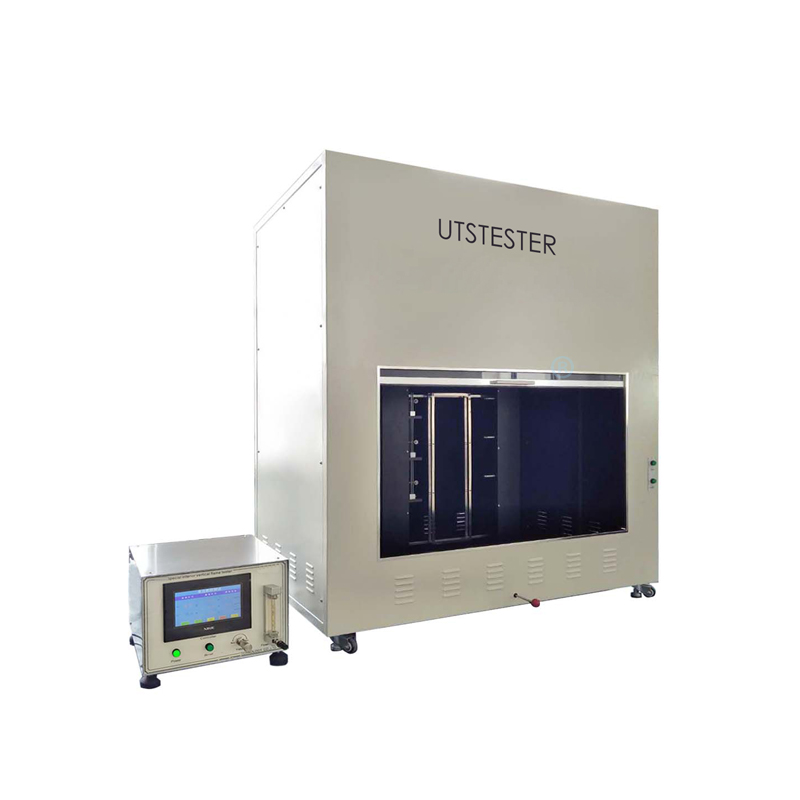

Introduction to flame retardancy testing: The flame retardancy of a material refers to the ability of a material or product to undergo flammable combustion under specified test conditions. It includes some characteristics related to whether it is easy to ignite and whether it can maintain the ability to burn. After years of development, flame retardancy testing has formed a variety of standards and has become a very important testing item in relevant industries.

Purpose of flame retardancy testing: By conducting combustion tests on samples provided by customers, and conducting corresponding grade ratings based on the combustion results, we assist customers in quality control of products. Flame retardant grade is one of the most important safety properties. It is essential for many certifications and is also a mandatory inspection item required by many countries.

Flame retardant testing application scope: mainly used in plastics, foam plastics, films, textiles, coatings, rubber, automotive interior parts, electrical and electronic products, etc.

Testing standards:

1.GB/T 2408-2008 Plastics - Determination of combustion properties - Horizontal method and vertical method

2.GB/T 5169.16-2008 Fire hazard test for electrical and electronic products Part 16: Test flame 50W horizontal and vertical flame test method

3.GB 4943.1-2011 Information technology equipment safety Part 1: General requirements

Flame retardancy test steps:

Sampling→Pretreatment→Turn on the machine and adjust the fixture height, flame height, gas flow, etc.→Test and record the results→Grade according to the standards.

Vertical combustion terminology explanation:

afterflame: The continued flame of a material under specified conditions after the ignition source is removed.

afterflame time (t1 and t2): the duration of afterflame.

afterglow: After the flame terminates, or when no flame is generated, and after the ignition source is removed, the continuous glow of the material under specified test conditions.

afterglow time (t3): The duration of afterglow.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com