+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

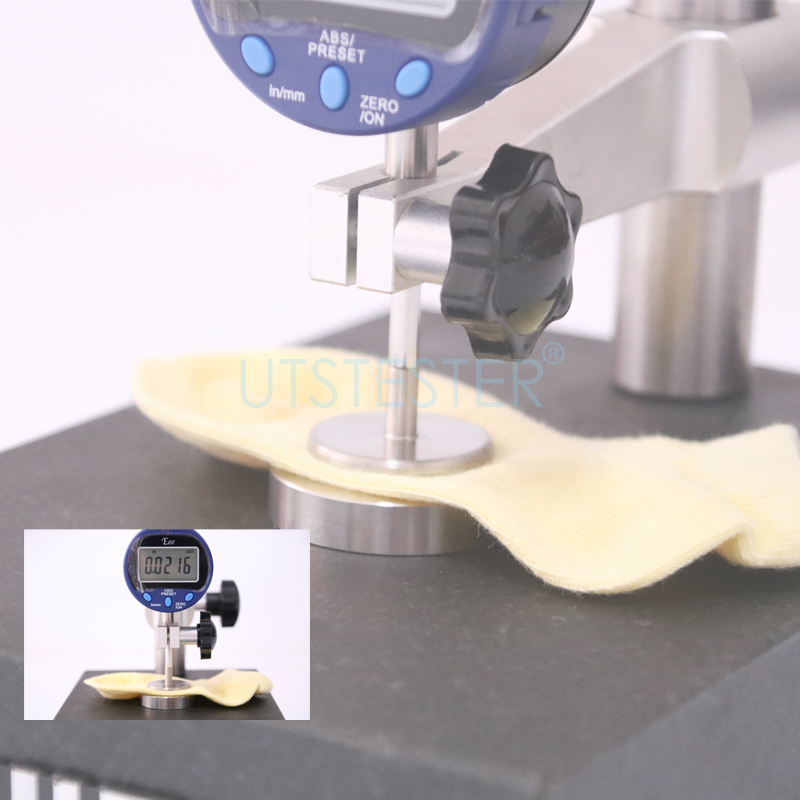

The environmental conditions of the laboratory should be paid attention to when the fabric thickness gauge is used. The levelness of normal laboratory worktable can meet the requirements of fabric thickness gauge, which can be put into use as long as the balance is placed on the worktable. The preparation of the sample is in accordance with the relevant standards, and the thickness gauge board has a large space, so the general thickness measurement does not necessarily require cutting the sample. The fabric thickness gauge needs only one person to operate independently. The operator records the test data and then sorts them into the test report.

If the instrument is temporarily out of use, it needs to be properly maintained. Fabric thickness gauge is simple and reliable in structure and convenient in maintenance. Care should be taken to prevent the invasion of dust, oil, water or other liquids. Cleaning should be done. The driving part of fabric thickness gauge adopts dust-proof rolling bearings. To ensure its flexible movement, it is lubricated with clock oil. If necessary, a small amount of clock oil can be added.

If the instrument has been used for a long time, then the instrument needs to be calibrated. Generally, it can be defined as half a year or one year according to the test working time. How to check the method is shown in the random instructions.

A few final tips:

1. The power supply used shall be well grounded to ensure the safety of operators and instruments.

2. When not in use or when changing the presser foot, place the protective sponge between the presser foot and the datum plate to protect the working face from damage.

3. Avoid oil, water or other liquids from invading into the digital display, otherwise it may cause damage to the instrument.

4, should avoid to use in high temperature and high humidity environment, the working temperature should be between 0 ℃ to 40 ℃, relative humidity of 80% or less, so as not to affect the precision of the instrument.

5. When the digital display table is not in use for a long time, the battery should be taken out.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com