+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

+86 152 6060 5085

Blog

Catalog

Latest Blog

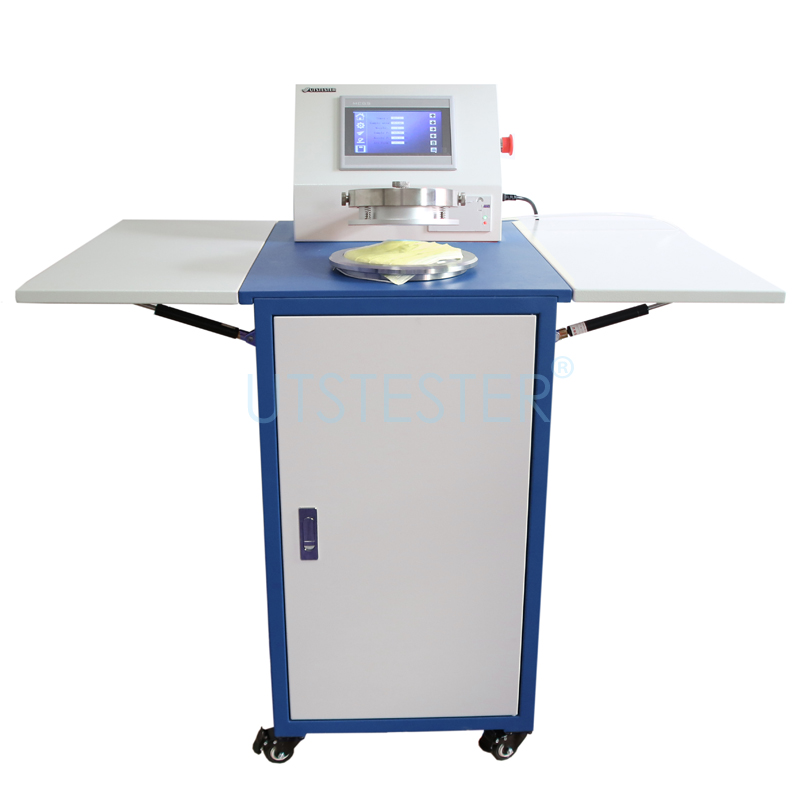

Fabric breathability meter is a special instrument for testing fabric breathability. The international popular breathability meter has three kinds of measurement units for flow rate: hole plate type, circular nozzle type and flowmeter method.Among them, domestic general way is former 2 kinds.It is stipulated in GB/T2624 and ISO5167.The last method, which USES a flowmeter, has few users because of its small test range.The air permeability meter adopts high precision pressure sensor to test the pressure difference between two sides of the sample, calculates and measures the flow rate through single chip microcomputer, and can realize the air permeability and air permeability.

In the practical use of many products, permeability test is a hard indicator, and relevant standards such as GB/T5453, ISO9237, ASTM D737, ASTM D3574, BS5636, JIS L1096 and other standards have basically the same requirements on permeability.When testing samples according to the standard, the test results of different instruments are different. What is the reason?Some say the nozzle or orifice was the cause, and cite a large amount of data to try to prove their point.Apart from the dispersion of the sample itself, there are many reasons for the different test results.However, the real reason is not the use of nozzle or hole plate.Regardless of the test approach, the immediate key factor is the traceability of the original data.

A lot of people use fabric ventilators a lot, but the average user, what's going on with the raw data of a breathalyzer, is often a bit of a cloud.Encounter data deviation, often in the mechanical design of the instrument to find the reason, this is precisely the performance of amateurs.A complete breathable meter has at least thousands of original test data behind each test orifice or nozzle. Combined with different test orifice plates and a large amount of test data, the final original data is often tens of thousands.Combined with these accurate data, the data of test nozzle or orifice plate is revised, that is, the more accurate the original data is, the smaller the deviation of test results will be.Therefore, no matter using imported instruments or domestic instruments, no matter whether nozzle type or hole plate type design, the original data is sufficient and accurate, and good experimental data will be obtained in accordance with the test conditions stipulated in the standards.In order to verify the difference between the experimental results of hole plate type and nozzle type, the International High Technology RESEARCH and Development Center specially developed two different breathable instruments for scientific comparison experiment.By revising the original data of nozzle type and orifice type, good linear test results are obtained.Difference is the hole plate design, use the card to replace, nozzle type greatly improve the test efficiency, the same time, the orifice plate is three times bigger than the nozzle type work efficiency first, visible, choose nozzle and pore permeability instrument panel, regardless of the test efficiency and working strength etc. The reasons, two ways are feasible, the specific use which kinds of means, depending on the user's habits.

In addition, conventional laboratory instruments and equipment play an important role in the process of scientific research and experiment, promoting the innovation and development of science and technology.Without the overhaul and maintenance of the instruments and equipment, any scientific research and test work can not be carried out smoothly.Therefore, the general textile laboratory needs to be equipped with professional maintenance staff of conventional instruments and equipment, and enhance their service awareness.

Failure 1: When the power switch is turned on, the device does not have any display, and the screen and power display light are not on.

Possible cause: Power supply problem. Check the supply.

Possible cause: a broken fuse.

To check or replace the fuse, unplug the instrument and unscrew the fuse knob to remove the fuse. If the fuse needs to be replaced, use a fuse of the same rated current.

Fault 2: If the error range is out of tolerance during calibration and gas leak check.

Possible causes: Check whether the sample orifice plate is compressed, and whether there is air leakage.

Possible causes: Check whether the sample pressing device is flexible and whether the tightening ring is tight.

Possible reasons: suction hose and flow simplified, suction fan connection whether leakage.

Possible cause: leakage of air in the lock seal rubber ring on the flow cylinder door.

Fault 3: Press the button, the instrument does not respond.

Possible cause: the button is broken.

Our laboratory staff can basically solve the routine faults of the general fabric breathability meter. If there are any problems such as procedures, we must contact the professional engineer of the manufacturer to solve them. It is absolutely necessary not to disassemble without permission, so as not to cause greater losses.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com